OGMP 2.0:

Comparing Direct Measurement Requirements with the Revised EPA Subpart W Rule

June 4, 2024

By: Elizabeth McGurk

Our OGMP 2.0 blog series has addressed the following topics:

- The what and the why of OGMP 2.0;

- Elements of an explicit and credible implementation plan; and

- How to launch a successful OGMP 2.0 direct measurement campaign.

This fourth installment of this series, below, discusses the greenhouse gas (GHG) regulatory landscape in the United States and how OGMP 2.0 requirements overlap with recent revisions to GHG reporting rules.

Setting the Stage: The U.S. Methane Regulatory Landscape

The last several months have brought a flurry of rulemaking related to greenhouse gas (GHG) emissions from the oil and gas industry, both in the U.S. and abroad. Most recently, the U.S. EPA released the finalized pre-publication text of Subpart W, which is the U.S. GHG Mandatory Reporting Rule (MRR) that applies to the oil and gas industry.

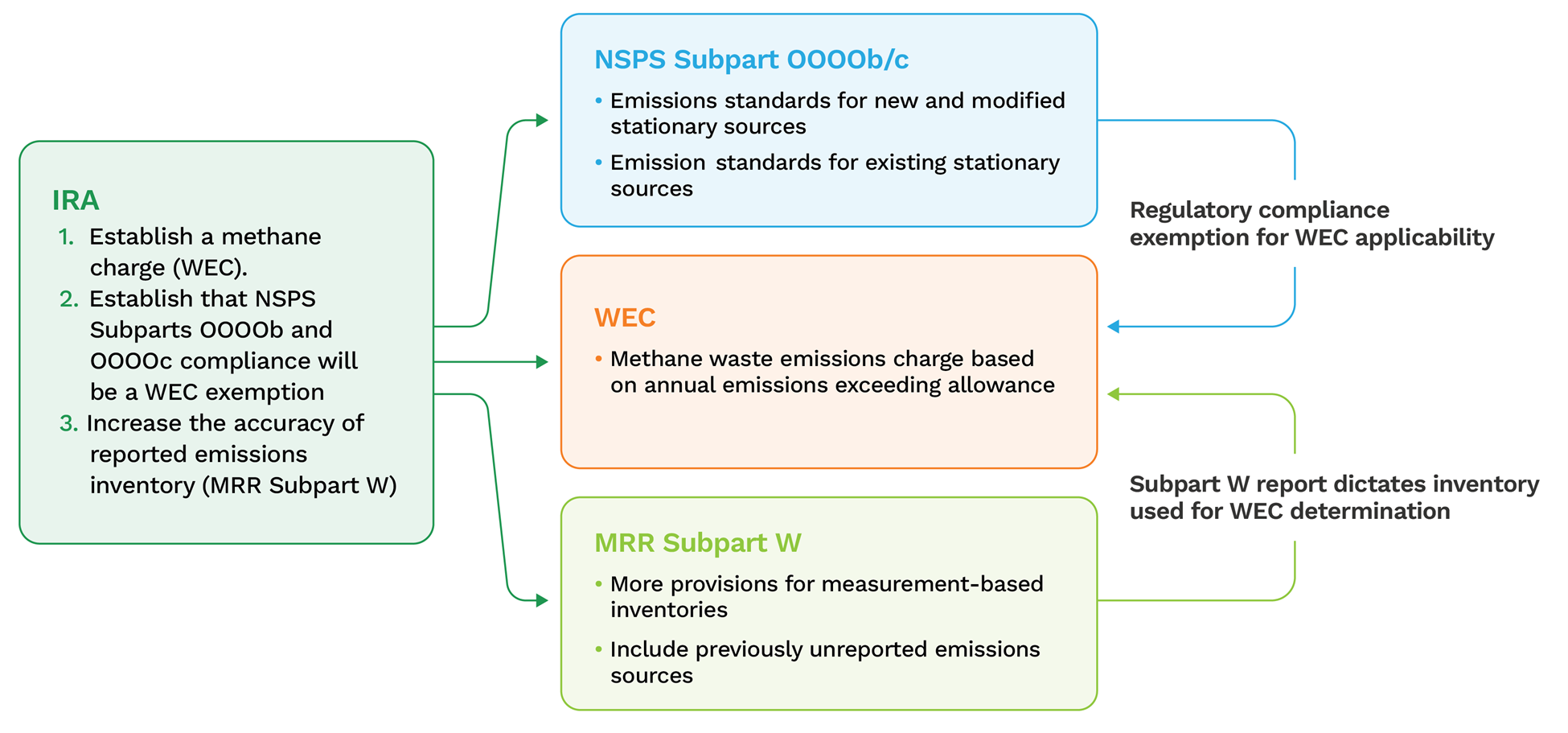

At a high level, revising Subpart W is part of a three-pronged regulatory update that was mandated to U.S. EPA by Congress through the Inflation Reduction Act (IRA) as part of a strategy to drive down methane emissions from oil and gas operations.

The revisions to Subpart W are intended to both increase the accuracy of reported GHG emissions and form the basis for calculating emissions subject to the U.S.’s first methane fee, through the proposed methane waste emissions charge (WEC). (For a breakdown of the changes included in Subpart W, see here.)

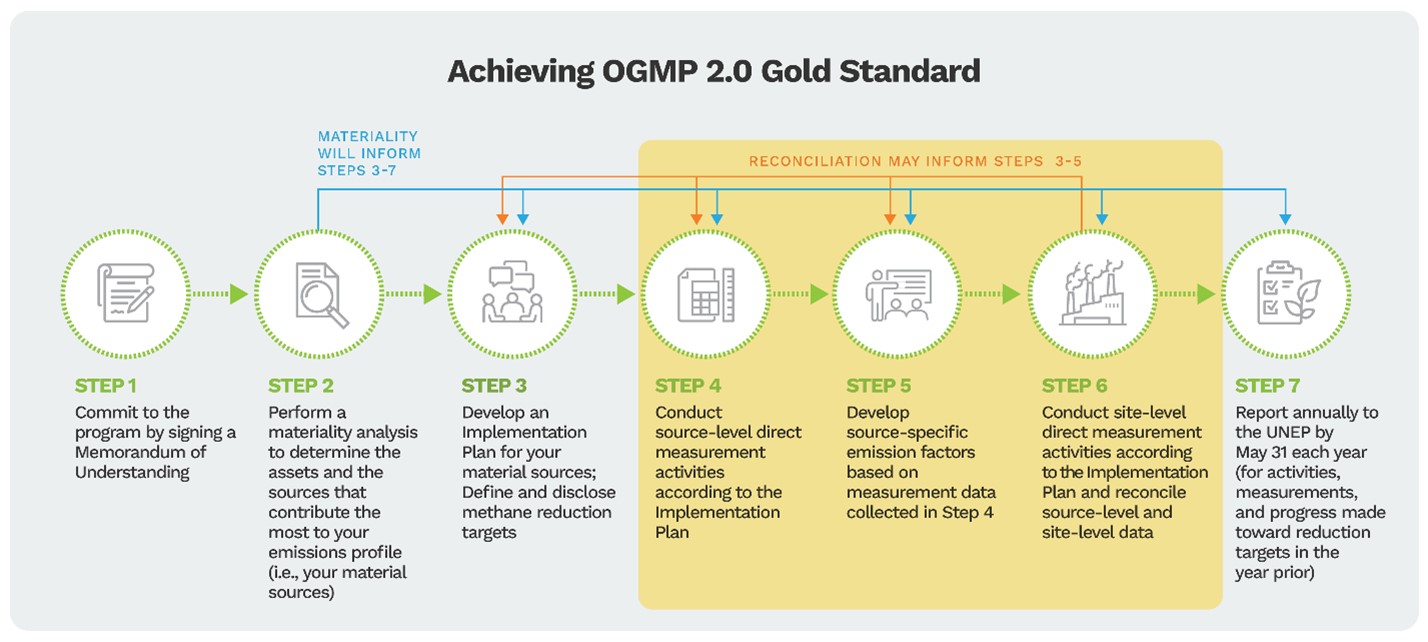

The Subpart W revisions aim to increase the accuracy of GHG reporting by (1) requiring the inclusion of emission sources that were previously not included in the report and (2) by allowing facilities to use empirical measurement-based data as a basis for reported emissions. As we have previously discussed, the backbone of achieving OGMP 2.0 Gold Standard is developing a measurement-based understanding of methane emissions to inform emissions reduction goals.

With the emphasis of both Subpart W and OGMP 2.0 on measurement-based emissions inventories, you may be wondering if OGMP 2.0 requirements and Subpart W requirements overlap and whether you can gain efficiencies by considering an OGMP 2.0 commitment concurrently with the development of Subpart W-compliant monitoring programs. This blog has you covered! See below for a comparison of OGMP 2.0 and the new Subpart W monitoring requirements, which are required beginning in Reporting Year 2025 (and optional in Reporting Year 2024).

Comparing and Contrasting OGMP 2.0 and Subpart W Monitoring Requirements

Both OGMP 2.0 and the revised Subpart W rule highly emphasize the value of using empirical, site-level data to develop accurate emissions inventories. See a high-level summary of the empirical data requirements for each program below.

| OGMP 2.0 | Subpart W |

|---|---|

| Level 4 source-level quantification required for a company’s most material emission sources (those that have the most impact on the methane emissions footprint). | For many emissions sources, operators can generally choose preferred methodology per category. |

| Level 4 quantification can be either through direct measurement or engineering calculations using site-specific data. | Allowable methodologies differ by emission source and generally include one or more options including: direct emissions measurement, measurement + engineering calculations, engineering calculations, or emission factors. |

| In an effort to maximize flexibility, the framework does not dictate specific technologies, measurement frequencies, or measurement protocols. | For direct measurement-driven calculations, Subpart W includes monitoring and technology requirements. |

| Measurement technologies must be fit for purpose to measure specific parameters of source emissions as outlined in the OGMP 2.0 framework and associated technical guidance documents (TGDs). | Provisions are available for seeking EPA approval on alternate and emerging technologies. |

| OGMP 2.0 allows the use of different technologies across assets. | Specifies per emission source category whether different technologies can be used. Generally, the same technology and measurement approach must be used either for an entire wellsite or reporting facility. |

| Recommendations for number of sources to sample to gain representative measurement data are outlined in the Uncertainty and Reconciliation TGD and vary depending on the population size, materiality of the emission source, and complexity of the emission source. | Generally, the same technology and measurement approach must be used either for an entire wellsite or reporting facility. In some cases, measurements can be split across reporting years. Subpart W requires a minimum number of measurements to develop some emission factors, regardless of population size or other factors. |

| OGMP 2.0 Gold Standard requires both source-level and site-level measurements of assets as well as reconciliation between source- and site-level measurements to verify completeness and accuracy of the emission inventory. | Focuses on source-level measurements. Site-level, top-down monitoring is allowed only for developing emissions estimates from “other large releases” (i.e., super-emitter events). |

Analogous Emission Source Categories

Both OGMP 2.0 and Subpart W require emissions reporting requirements by emission source type or category. OGMP 2.0 allows flexibility in determining technologies and methods for emissions quantification while Subpart W’s direct monitoring requirements are generally more stringent.

As shown in the following table, each OGMP emission source category has at least one corresponding Subpart W emission source category. Therefore, Subpart W-compliant monitoring programs can provide an excellent starting point to a robust OGMP 2.0 implementation strategy. See below for more discussion on specific source categories.

| OGMP Emission Source Category | Corresponding Subpart W Source Category Allowing Measurement |

|---|---|

| Pneumatics | Pneumatic Devices Pneumatic Pumps |

| Leaks | Equipment Leaks |

| Incomplete Combustion | Combustion Equipment |

| Flaring | Flare Stacks a |

| Reciprocating Compressors | Reciprocal Compressors |

| Centrifugal Compressors | Centrifugal Compressors |

| Unstabilized Liquid Storage Tanks | Hydrocarbon Liquid Storage Tanks Condensate Storage Tanks |

| Glycol Dehydrators | Dehydrators b |

| Incidents, Emergency Stops, and Malfunctions c | Other Large Release Events c |

| Liquids Unloading | Liquids Unloading |

| Gas Well Hydraulic Fracturing | Completions and Workovers with Hydraulic Fracturing |

| Other Purging and Venting d | Completions and Workovers without Hydraulic Fracturing Blowdown Vents Acid Gas Removal Associated Natural Gas |

| Oil Well Casinghead | Blowdown Vents |

a Some emissions vented through flare stacks are reported with other emissions source categories.

b Only glycol dehydrators allow the use of direct measurement. Dessicant dehydrator emissions are required to use generic emission factors. Dessicant dehydrator emissions are reported under the venting category for OGMP 2.0.

c Other large release events only include NSPS Subpart OOOOb super-emitters for Subpart W. The OGMP 2.0 source category is broader and includes all accidental releases.

d Other purging and venting, as defined by OGMP, is not confined to the Subpart W sources listed in this table.

Source-Specific Considerations

Based on our experiences in the OGMP 2.0 and measurement space, see below for some highlights on emission source categories that are generally most material to oil and gas operations’ emission footprint. Montrose’s world-class measurement teams have extensive experience measuring emissions from all of the emission sources listed below.

Equipment Leaks

- Subpart W allows three different methodologies for calculating emissions from equipment leaks.

- The first is using total counts of fugitive components and default emission factors.

- The second is based on surveying for leaks and using leaker-specific default emission factors that differ based on the technology used to detect the leak.

- The third is based on source-level measurements using a high-volume sampler or other approved technology. Subpart W allows the development of a facility-specific emission factor using measurements from 50 equivalent source types.

- OGMP 2.0 allows source-level measurements to develop basin-specific emission factors for use in Level 4 quantification. The minimum number of measurements is determined by collecting emission rate data from a representative sample of component types. The operator defines representative based on their asset.

Pneumatic Devices

- Subpart W allows three different methodologies for calculating emissions from pneumatic devices.

- The first is using equipment counts and default emission factors.

- The second strategy requires a 15-minute monitoring period and measurement of emissions during a normal actuation as the basis for the emissions estimate; when using this method; facilities in some industry segments have 2-5 years to monitor all devices, depending on their equipment count.

- The third is similar to the leaker strategy for equipment leaks discussed above. Each pneumatic must be observed annually for a 2-minute monitoring period. The counts of malfunctioning and normally operating devices are used with leaker and non-leaker factors to estimate emissions.

- OGMP 2.0 considers both the malfunctioning count and direct methodologies above as acceptable Level 4 quantification methods but prefers the combination of methods to include both an understanding of malfunction rate and emissions during normal operations.

Flares

- Subpart W allows a default destruction removal efficiency (DRE) of 92%. Site-specific NSPS OOOOb- or Refinery MACT-compliant monitoring is required to claim DREs of 95% or 98%, respectively. Alternate technologies employing direct measurement of DRE can be used to justify DREs exceeding 98%.

- OGMP 2.0 has traditionally considered direct measurement of DRE, i.e., through Video Imaging Spectro-Radiometry (VISR) or other technologies, to meet Level 4 monitoring requirements. Other Subpart W-compliant options would likely be acceptable when used consistently with Subpart W DREs.

Incomplete Combustion (i.e., methane slip)

- Subpart W requires the use of site-specific monitoring data (i.e., stack testing), if any testing is performed for a compliance or voluntary program, to be used in annual reporting. If source testing is not performed, it allows the use of default emission factors or manufacturer-provided data or certifications to quantify methane emissions resulting from incomplete combustion.

- OGMP 2.0 considers only direct measurement through continuous monitoring systems or stack testing as meeting Level 4 monitoring requirements.

Incidents, Emergency Stops, and Malfunctions

- Subpart W names this emissions category “other large releases” and confines it to confirmed NSPS Subpart OOOOb super-emitter events. Operators can use engineering calculations or site-level monitoring data to calculate emissions from these events.

- OGMP 2.0’s definition of this category is broader and includes all unintended accidental releases. OGMP 2.0 member companies often use engineering calculations for these estimations, but sensor data could be used as well. Note that OGMP 2.0 does not allow the same technology to be deployed for source-level and site-level inventory development for Gold Standard reconciliation.

Conclusion

The methane regulatory environment is evolving rapidly – and it can be a lot to keep up with. However, if you are committed to reducing methane emissions, the new requirements may also serve as the opportunity to make a sustainability-driven commitment. The revisions to Subpart W align well with OGMP 2.0 guidelines and a Subpart W-compliant monitoring program will help you on your pathway to OGMP 2.0 Gold Standard.

Related Montrose Resources

Elizabeth McGurk,

Elizabeth McGurk,

Managing Consultant, Climate and Sustainability Advisory

Elizabeth is a highly-experienced air quality program manager with expertise in the fields of greenhouse gas (GHG) quantification and mitigation, oil and gas sustainability framework implementation, regulatory analysis, and auditing. Her passion is in leveraging measurement-informed data to inform effective mitigation efforts, and she is proud to have supported OGMP 2.0 projects worldwide. Elizabeth has a strong background in delivering technical trainings and excels in distilling and presenting complex information, impacts, and solutions to various stakeholders. She leads diverse teams and has conducted complex environmental projects, both regulatorily and voluntarily driven, for clients in carbon-intensive industries. She specializes in assisting clients with Scope 1, Scope 2, and Scope 3 GHG emissions quantification and reporting as well as in developing practical, real-world carbon reduction strategies.