OGMP 2.0:

Effective Direct Measurement Campaigns

May 7, 2024

Tips for a Successful OGMP 2.0 Measurement Campaign

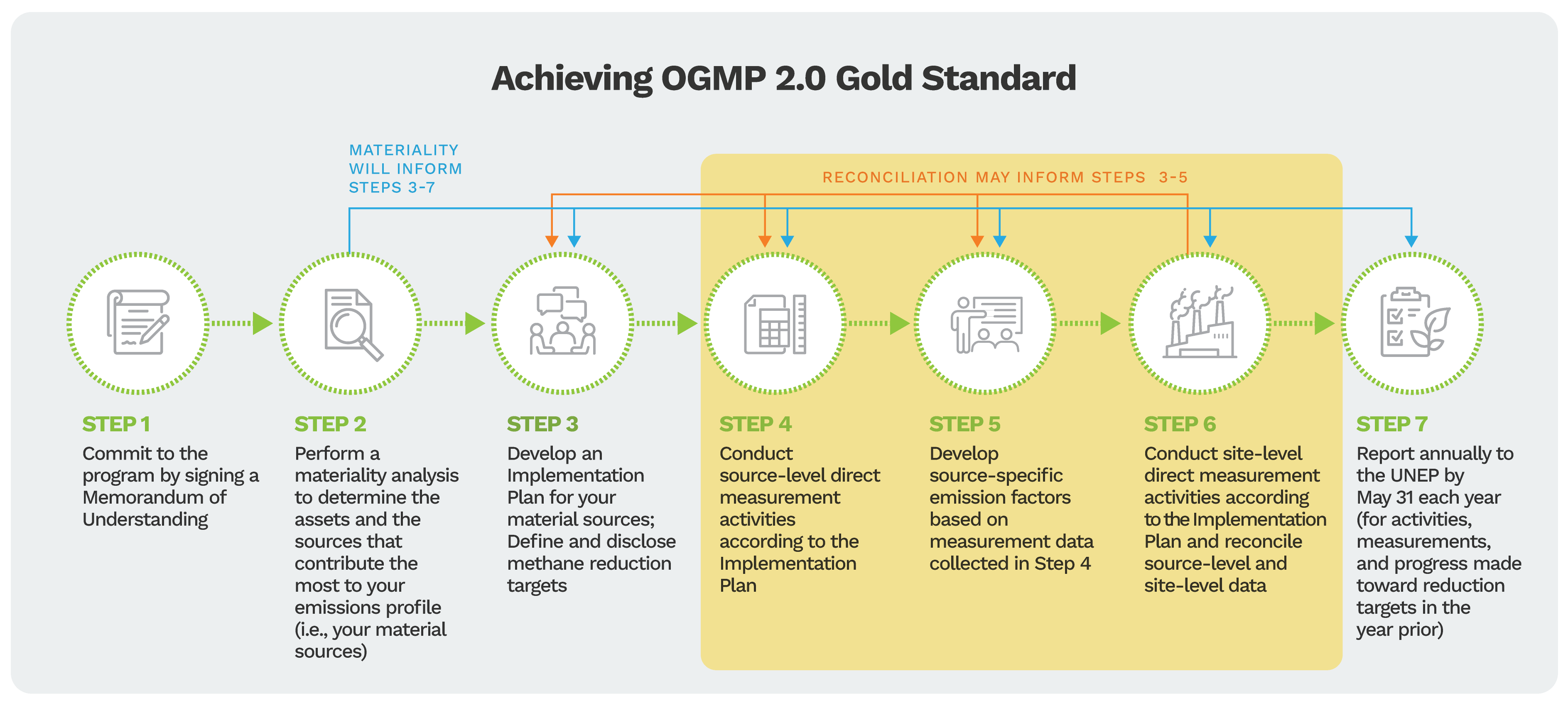

In Parts 1 and 2 of our OGMP blog series, respectively, we discussed the what and the why of OGMP 2.0, and the elements of an explicit and credible implementation plan. This third installment in the series offers perspectives on how to launch a successful OGMP 2.0 direct measurement campaign.

As we’ve discussed in previous installments, OGMP 2.0 Gold Standard is the destination, and the implementation plan is our roadmap. You’ve likely invested significant effort into making the decision to join OGMP 2.0 and developing an implementation plan, but the real work is about to begin. To continue our journey, we need to select our vehicle and we have a whole host of things to consider. Is this the correct vehicle, does the person driving have a license, are the tires bald, does it have enough fuel to get us where we are going, are there tolls we need to pay, do we have insurance, will we be driving straight into a blizzard?

It doesn’t matter if this is the first campaign, remeasurement, or an evaluation of new technology. There are some questions that you should be asking internally and externally from the stakeholders in your measurement campaign to make sure all parties are well prepared. This is an instance where, as Dr. Franklin so famously said, “an ounce of prevention is worth a pound of cure”. It can be challenging enough under the given circumstances to measure a single source, and this can be extrapolated when dealing with multiple technologies at once or emerging technology.

Pre-Deployment Considerations

Before we start sending teams into the field to collect direct measurements, if that is the chosen approach, we need to consider a few things that will inform our program. Hopefully our well-prepared implementation plan informs us as to our approach on a macro level, but we need to be sure we have a plan for our field teams externally and internally, or our exercise may not have been addressed in our implementation plan at all. Though your mileage may vary, a general list of some of the questions we recommend asking is listed here. As you can see the list is long, and these are just a few general concerns. This list becomes even longer when we start to consider an international component to the project. When we start to drill down into these considerations one can get a sense of how much planning is going into a measurement technology campaign.

Pre-Deployment Considerations

- Are there specific risks and safety concerns?

- What are the desired outcomes/goal?

- who are the stakeholders?

- What equipment category will be sampled?

- Where is the equipment located?

- Is the equipment stationary?

- What are the operating conditions?

- What technology will be deployed?

- Is the technology appropriate for the source?

- What are the logistical concerns?

- What needs to be included in my test

International Considerations

- Visa/Work Permits

- Customs clearance

- Tax

- Export controls

- Residency Requirements

- Dangerous goods shipping

- Equipment durability

- Crating/labeling

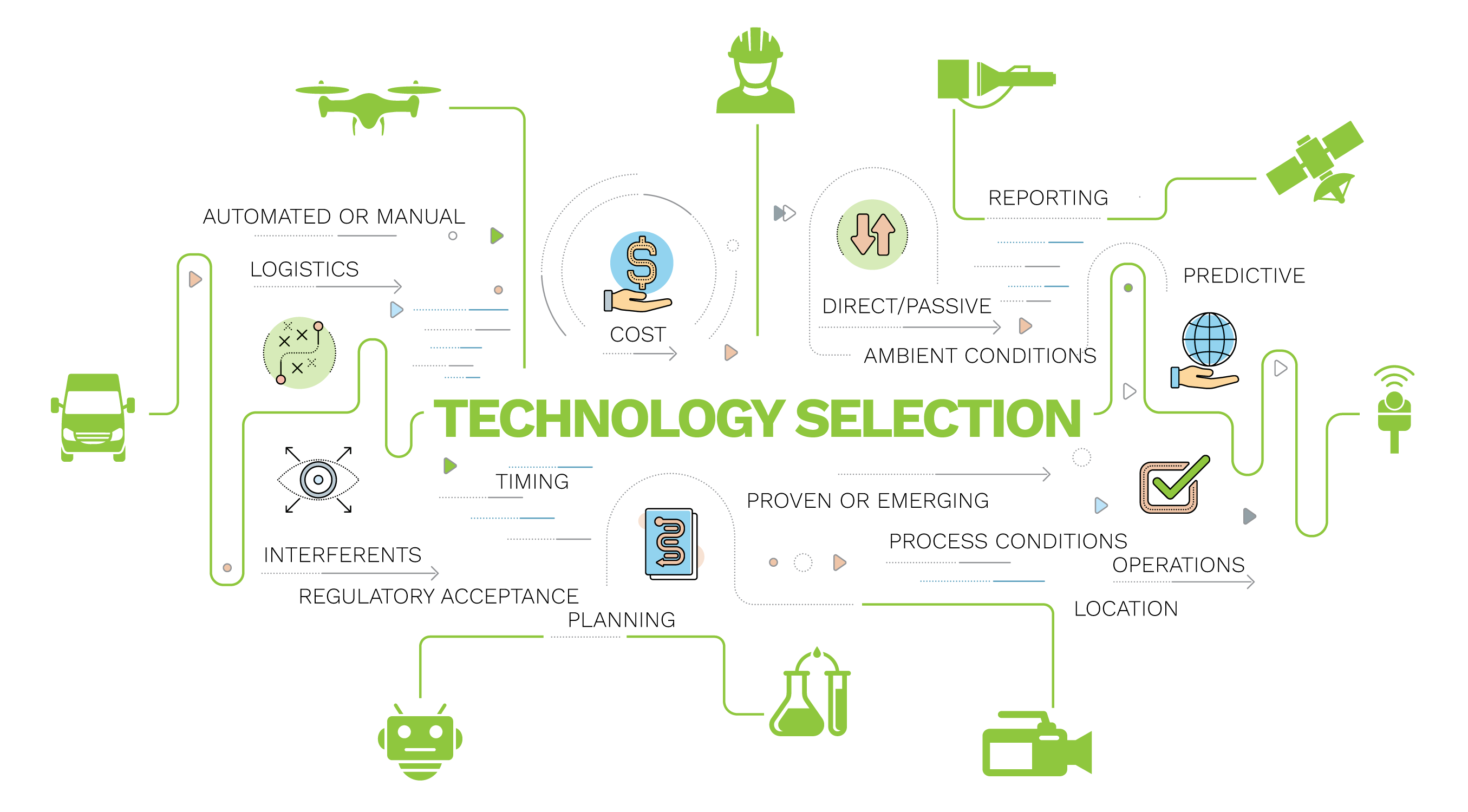

Technology Selection

I compare choosing one or more measurement technology to selecting a car for this part of our journey. This is an interesting time when it comes to technology – it seems like a new measurement option becomes available daily. I have been working directly with measurement technology for the last 20+ years, and there have been more new ways to measure, quantify, and detect methane emissions developed over the last few years than in the preceding 20. As a potential consumer of this technology the market can get extremely confusing. Is that the same sensor/detector with a different colored box covering it being sold by 29 different companies? Maybe. Is a Chevy Cobalt different from a Pontiac G5, and more importantly are either of those the correct choice to get us to our destination?

Don’t worry because OGMP 2.0 probably just dictates what we must use anyway right? Nope.

If you want to read exactly what UNEP says, you can find that here: https://ogmpartnership.com/faq/, but the long and the short of it is that they don’t recommend a specific technology, but they reserve the right to tell you after the fact that your data is not fit for the intended purpose. Sound scary? Perhaps, but it doesn’t have to be.

Being technologically agnostic is great from a flexibility standpoint. We have an entire toolkit full of existing technology to rely on and many new technologies that are actively targeting our dollars. There is a lot at stake for selecting one that meets our needs and represents good value. That value may be in that it provides insight into how our equipment is operating, or maybe that it serves a compliance purpose at the same time.

Another important question we should be asking is will the data be defensible? This is where existing technology may have an advantage because a longer history of results coupled with potentially a more well-developed method for application.

It turns out that trying to pick out the right Johnny 5 could be causing us to short circuit (sorry I couldn’t resist). With thoughtful consideration for the desired outcome, we can alleviate some of the risk and anxiety (and noise) and focus on getting the desired outcome while we enjoy our more comfortable ride to Gold Standard. We recommend engaging measurement technology experts – operators and/or consultants – to complete a technology review before you reach the point of vendor engagement.

Test Plan and Field Measurements

We now have decided on a fit for purpose measurement technology, and we have nailed down the who, where, when why and how. Time to take some measurements!

We did forget to let the operators know we were coming, and the process instrumentation was down so we have no operating data to support the measurements. This is why we strongly recommend having a fully reviewed test plan developed and approved by all relevant stakeholders prior to initiating a measurement campaign.

Test Plan Elements

- Identify – Clearly identify emission points and process conditions.

- Understand – Understand emission points – release parameters, stack conditions, location access

- Choose – select the most appropriate measurement technology

- Define – define data collection expectations based on intended analysis

- Involve – involve site personnel to ensure proper access and data collection

We may spend a lot of time planning and that can mean that there is a large gap of time between the initial phases of the project and the end. A well-written test plan will serve as a reference if there are personnel changes along the way or equipment maintenance that is scheduled at the same time the testing is going to take place. Proper planning and an experienced and engaged field team can ensure that the professionals we have operating measurement technology in the field collect the right data of good quality. It will also inform internal staff on their roles and responsibilities during the testing.

Reporting

This is the last step of our process, and possibly the most important in terms of achieving true methane emissions mitigation objectives. Collecting data is key, but it is also important how we apply the data we collect. I’m not generally a fan of the measurement for measurement’s sake approach. The overarching goal of all methane-related frameworks is to reduce the amount of methane being released into the atmosphere. If our measurements aren’t informing us about methane emissions and where we have the best opportunity to reduce our methane footprint, why are we collecting the data in the first place? That isn’t to say that every measurement campaign will give us the expected outcome, but if we have well- established parameters, the data can still be valuable and defensible.

Report Elements

- Who is compiling the data?

- Can it be correlated?

- Is the data defensible?

- What were the outcomes?

- What are the lessons learned?

- What conclusions can be drawn from the data?

- How will this be applied to my OGMP 2.0 reporting?

- Will I also be using this report to satisfy a regulatory requirement

Conclusion

A successful measurement technology measurement campaign will be difficult but should also be a valuable learning experience. Putting in the work in advance and remaining diligent throughout the process can provide a sense of security that the desired outcome will be achieved. If the results are unexpected and the process was documented properly, and data collected rigorously throughout they can still inform us and prove valuable.

In the next blog, we will talk about some of the synergies and shared benefits between OGMP 2.0 and other regulatory compliance programs.