Points of clarification needed from PHMSA on its proposed pipeline safety rules

September 20th, 2023

A summary of PHMSA’s rule proposal

In May of 2023, the Pipeline and Hazardous Materials Safety Administration (PHMSA) published a series of proposals that, as written, would impose specific technical standards for leak detection and repair (LDAR) equipment. By establishing performance thresholds, the agency hopes survey technicians will quickly detect the kinds of small gas leaks that remain elusive under current PHMSA regulations but contribute to long-term environmental harm when unintentionally allowed to persist.

As noted in the proposed rulemaking document, these technical standards would impact:

- 7 million+ miles of pipelines, along with pipeline facilities

- 403 underground natural gas storage facilities (UNGSFs)

- 165 liquefied natural gas facilities (LNGs)

The proposal also seeks to increase survey frequency relative to the type of facility, again with the goal of promoting earlier detection and repair. Additionally, PHMSA wishes to require that advanced leak detection programs (ALDPs) adhere to guidelines that span four key areas:

- Commercially available advanced leak detection equipment

- Written procedures for leak detection

- Prescribed survey frequencies

- Program evaluation

While the PHMSA document explores each of these four areas in detail, my primary concern is with the first, which is the one that covers technical requirements for leak detection equipment.

OGI, no? Or yes? Where clarification regarding LDAR equipment is needed

As written in its proposal, PHMSA suggests that: “Any leak detection equipment used must have a minimum sensitivity of 5 ppm or less. A reading of 1% of the lower-explosive limit of methane gas at atmosphere is approximately 500 ppm; a minimum sensitivity of 5 ppm would therefore provide a protective threshold of detection sensitivity. That threshold is also consistent with the performance of commercially available leak detection equipment.”

This appears to mean that optical gas imaging (OGI) equipment would be barred from use under PHMSA’s proposed rule. An OGI camera can’t detect a leak at or below 5 parts per million (ppm). So, it’s an open and shut case, right? Not exactly. Elsewhere in its document, PHMSA states that: “an ALDP must be capable of detecting all leaks that produce a reading of 5 ppm or greater of gas when measured from a distance of 5 feet from the pipeline, or within a wall-to-wall paved area.”

Just like that, OGI seems to be back in the game. While an OGI camera can’t detect a leak at or below 5 ppm, it can more than likely detect one that’s producing a plume with a concentration of 5 ppm five feet from the source. When you compare the two paragraphs I’ve laid out, it’s clear there’s a discrepancy in the ruling’s language. Fortunately, PHMSA made its rule proposal public so that we in the industry can highlight and comment on these sorts of red flags. And that’s exactly what we should do.

One other point of concern: The PHMSA approval process

PHMSA does write that it would give operators the ability to create and submit a program for review that utilizes alternative leak detection technology, even technology that is less sensitive than its 5 ppm requirement. My concern here is this:

Does PHMSA have the bandwidth to review programs in a timely manner?

I don’t have the answer to that question, but I’m concerned that PHMSA might be biting off more than it can chew, especially given the number of facilities this ruling would impact.

If PHMSA’s rule proposal went forward as written

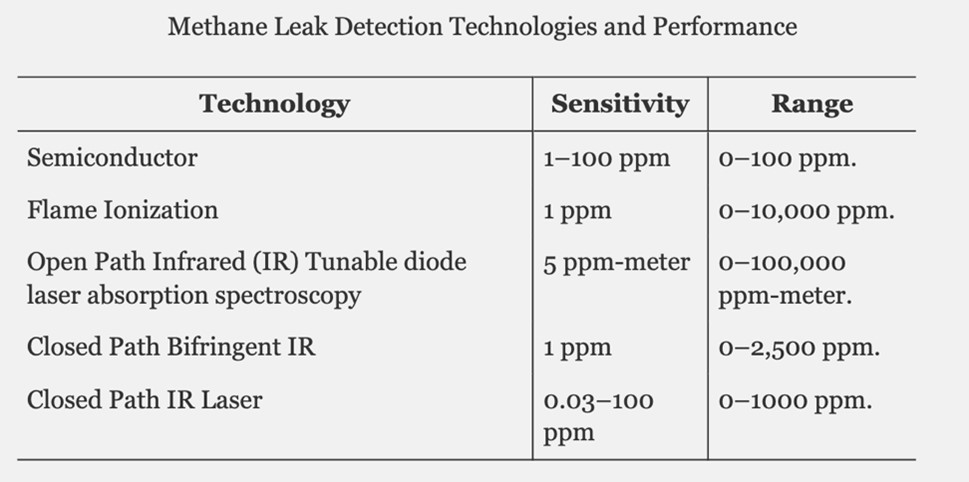

Given the lack of clarity regarding the use of OGI cameras for leak detection, the best advice I could give if this proposed rule became the law of the land today is to use both an OGI camera and one of the proposed rule’s approved technologies as listed in its chart below:

Taken from PHMSA rule proposal

In other words, rely on the OGI camera for your initial sweep. Rest assured, if the camera doesn’t visualize a leak, then you’ll have your approved device that should detect it. By coupling the OGI camera with an analyzer of this level of sensitivity, you’ll cover the requirements of the 5 ppm threshold while still benefiting from the efficiency that OGI technology provides. I fully expect PHMSA to provide clarity on this matter. But it never hurts to have a backup plan.