Navigating the Challenges of OOOOb Compliance: Compressor Venting Requirements for Oil and Gas Operators

July 9, 2025

By: Kaleb Meihls, Elizabeth McGurk, Ed Capozzi

Since the EPA’s NSPS Subpart OOOOb took effect in May 2024, oil and gas operators have been navigating a complex regulatory landscape. Developed under the Clean Air Act to curb methane and volatile organic compound (VOC) emissions—particularly from compressor vents—OOOOb introduces stringent monitoring, measurement, and reporting requirements that can strain technical and operational resources.

The scope of the rule is broad and applies to all compressors constructed, modified, or reconstructed after December 6, 2022, except those located at well sites (which is defined by the rule). Affected facilities must comply with applicable requirements. This impacts everything from capital project planning to ongoing maintenance strategies. The first annual compliance report is due August 5, 2025, and a technically demanding aspect of the regulation involves compressor seal vent measurements.

This blog draws on Montrose’s field experience to share actionable insights for operators preparing for their first full year of compliance.

Compressor Vent Measurement and Compliance

NSPS Subpart OOOOb seeks to reduce emissions from compressor seal vents. For centrifugal compressors, operators must either:

- Install a closed vent system,

- Use an emissions control system, or

- Conduct emissions measurement to verify emissions are below allowable limits.

For reciprocating compressors, emissions measurement is required to demonstrate compliance.

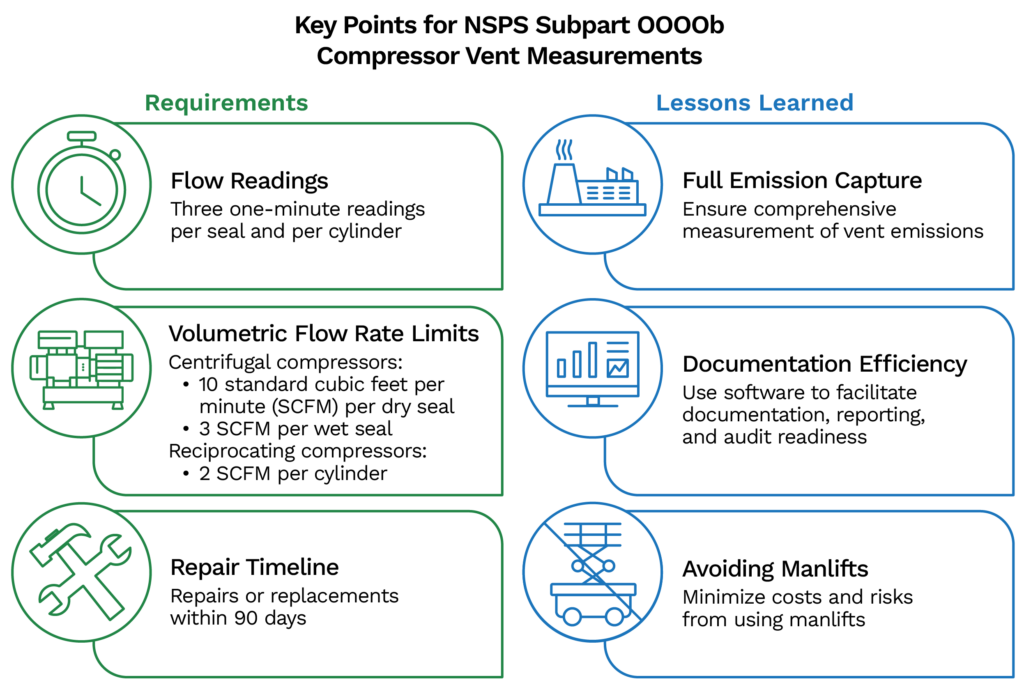

When collecting compressor vent emissions measurements, operators must collect three one-minute flow readings for each component, dry seals, wet seals, and rod packing vents. These readings must fall within 10% of each other and not exceed the following volumetric flow rate limits:

- Centrifugal compressors:

- 10 standard cubic feet per minute (SCFM) per dry seal

- 3 SCFM per wet seal

- Reciprocating compressors: 2 SCFM per cylinder

If these thresholds are exceeded, repairs or replacements must be completed within 90 days. Vent flow measurements are required every 8,760 hours of operation, placing an ongoing technical obligation on operators to maintain and validate compliance.

Compressor Vent Measurement: Lessons Learned and Best Practices

Montrose has assisted clients with NSPS Subpart OOOOb vent measurements for over a year, building on years of compressor seal vent testing experience under GHG reporting rules. Several key lessons have emerged:

- Full Emission Capture Is Essential

Precise measurement begins with comprehensive vent capture. Montrose’s proprietary, purpose-built full capture systems—designed in-house—enable safer, more accurate testing while avoiding the need for manlifts. These innovations reduce operational costs and safety risks while increasing data quality.

- The Right Technology Makes a Difference

The SEMTECH HI-FLOW 2 is a critical tool for measuring methane emissions accurately. It captures and analyzes the full exhaust stream, delivering real-time volumetric flow and concentration data. Montrose is an authorized distributor of the HI-FLOW 2, enabling us to both use and deploy the technology across the industry. This dual role allows us to support clients through expert services and through training and product access.

- Streamlined Data Management Is a Must

The data generated during these tests must be collected, validated, and reported in accordance with EPA formatting and deadlines. Tools like Target Online, Montrose’s proprietary software platform, support real-time data capture, facilitate timely reporting, and improve audit readiness. Integrating these tools into existing workflows requires dedicated process alignment, but the long-term efficiency gains are significant.

- Documentation Standards Are Still Evolving

Operators continue to face uncertainty around inspection protocols and audit expectations. Until enforcement becomes more standardized, the best strategy is to maintain meticulous records and clearly documented methodologies that demonstrate proactive compliance efforts.

Together, these lessons underscore that NSPS Subpart OOOOb compliance isn’t just about checking a box—it’s about implementing smart, efficient systems that keep operators ahead of regulatory pressure while enhancing operational performance.

Bringing the Latest Offerings to Meet NSPS Subpart OOOOb Compliance

Montrose brings a wealth of experience and proven capabilities to operators facing the complex demands of NSPS Subpart OOOOb. Performing approximately 10,000 vent and rod packing measurements annually across the U.S. and Canada, we have developed deep expertise not only in precise compliance measurement but also in training operators on industry best practices—helping them maximize efficiency amid resource constraints.

Conclusion: Actionable Insights for Operators

The path to full compliance under NSPS Subpart OOOOb is complex, but it’s manageable with the right strategy and support. Key takeaways for accurate emissions measurement include:

- Invest in the right measurement technology

- Prioritize complete emission capture

- Maintain thorough, audit-ready documentation

For oil and gas operators seeking a proactive, technically sound approach to regulatory compliance, Montrose offers the tools, talent, and track record to get you there. Connect with us to explore how we can advance a more compliant, sustainable future in oil and gas while continuing to drive meaningful progress across the industry.

Continue Reading

Kaleb Meihls

Kaleb Meihls

Business Development Manager

Kaleb is a resourceful and solutions-oriented Business Development Manager on Montrose’s U.S. Air Compliance team. With over eight years of experience in environmental services and account management, Kaleb has a proven track record of exceeding expectations, driving strategic growth, and building lasting client partnerships. Known for his independent approach and strong technical understanding, he helps clients navigate complex air compliance challenges with tailored solutions that prioritize both regulatory confidence and operational efficiency.

Elizabeth McGurk

Elizabeth McGurk

Methane Sector Leader

Elizabeth is a highly-experienced air quality program manager with expertise in the fields of greenhouse gas (GHG) quantification and mitigation, oil and gas sustainability framework implementation, regulatory analysis, and auditing. Her passion is in leveraging measurement-informed data to inform effective mitigation efforts, and she is proud to have supported OGMP 2.0 projects worldwide. Elizabeth has a strong background in delivering technical trainings and excels in distilling and presenting complex information, impacts, and solutions to various stakeholders. She leads diverse teams and has conducted complex environmental projects, both regulatorily and voluntarily driven, for clients in carbon-intensive industries. She specializes in assisting clients with Scope 1, Scope 2, and Scope 3 GHG emissions quantification and reporting as well as in developing practical, real-world carbon reduction strategies.

Ed Capozzi

Ed Capozzi

Business Development Manager

Ed is a Business Development Manager for Montrose Environmental’s LDAR team, specializing in emissions compliance solutions, Optical Gas Imaging (OGI), and regulatory-driven leak detection programs. With a background in Saas, IoT, automation, and industrial services, Ed brings a strategic, data-driven approach to helping clients navigate complex compliance challenges. With over a decade of experience, Ed has a proven track record of building lasting client relationships. His expertise spans LDAR compliance, emissions testing, and environmental regulations, making him a valuable resource for industries seeking to optimize their compliance programs.