Transitioning from PFAS Firefighting Foam to Fluorine-Free Alternatives – Part II

October 16, 2023

By: Dave Kempisty, Ph.D., P.E. and Nicole Bolea, P.E.

Introduction

In the second part of our blog series, we delve deeper into the critical steps that should be taken when transitioning from Aqueous Film Forming Foams (AFFF) containing per- and polyfluoroalkyl substances (PFAS) to synthetic fluorine-free foams (SFFFs). To learn more about SFFFs read our first installment here. In this blog, we will focus on four key aspects: scoping your project, partnering with an experienced team, cleaning the asset, and minimizing waste. These elements are vital in ensuring a smooth and environmentally responsible transition while maintaining effective fire protection. Continue reading for a detailed exploration of each of these essential factors in our ongoing discussion on this important shift to adopt new PFAS-free foams.

Firefighting foams have historically played a critical role for firefighting agencies and industrial emergency services worldwide, offering a swift and efficient method to combat fires, particularly those involving flammable liquids. PFAS-containing-AFFF have been favored in the industry for their superior and consistent performance. However, due to growing apprehensions regarding the environmental and human health hazards associated with PFAS, there is now a shift toward SFFFs. Making the transition isn’t as easy as a simple drop-in replacement of SFFF for PFAS-containing-AFFF. Cleaning legacy systems must occur to avoid contaminating the new SFFF with residual PFAS remaining in the system. Logistics, waste disposal, and maintaining ongoing fire protection during the transition must be considered. Stay tuned for future insights on human health impacts of PFAS, and their environmental presence and movement.

Scope the Project

Effective planning is essential to ensure a successful project. This involves a comprehensive assessment of current systems, clear identification of objectives, and a well-defined schedule outlining the assets and completion targets for the project. These aspects are crucial in developing a client-centered, site specific solution that is optimized and cost-effective. Planning should also encompass considerations for potential system modifications, potential replacement of declining infrastructure, and redesigns to enhance overall fire suppression system performance. It’s important to document workplace exposures, ensuring occupational health and safety and aiding in managing any future liability. In addition, overseeing project quality, thorough data management and validation, and efficient schedule management to minimize fire suppression system downtime are equally vital in scoping the transition project.

Partner with an Experienced and Trusted Team

It’s important to partner with a technical field services team that brings extensive experience in AFFF change-out projects. An established track record providing proven turnkey technology and techniques and with knowledgeable operators is key to a successful project. Team experience with the following tasks is important to consider.

- Efficiently draining and containerizing AFFF concentrate with appropriate secondary containment requirements.

- Effectively decontaminating and flushing of AFFF-containing tanks, hydrants, and piping networks to pre-established client treatment objectives.

- Capturing and containerizing the rinsate generated during this process with an emphasis on minimizing waste generation requiring disposal.

- Treating rinsate to avoid high disposal costs with safe discharge, whether to the storm or sanitary sewer or directly into the environment.

- Demonstrated experience in the management, transportation, and disposal of any liquid or solid waste generated during the process.

Figure 1 – Partnering with an experienced team with AFFF transition experience is important for project completion on time and on budget. Understanding the planning, logistics involved, and environmental safety and occupational health considerations such as secondary containment are important to a successful transition.

Collaborating with a seasoned expert in the field is crucial, but it’s equally vital to engage a team that provides all-encompassing comprehensive services. Fragmenting various aspects of the transition can lead to extra expenses, scheduling conflicts, and prolonged project timelines. It’s preferred to have skilled operators with access to efficient treatment technology, a clear understanding of the occupational safety and environment aspects of the project and access to in-house accredited and certified analytical laboratories to ensure goals are achieved. From the analytical laboratory perspective, certification with applicable methods, state-of-the-art facilities, and experience handling PFAS-impacted environmental samples with appropriate quality assurance and control are all important.

Clean the Asset

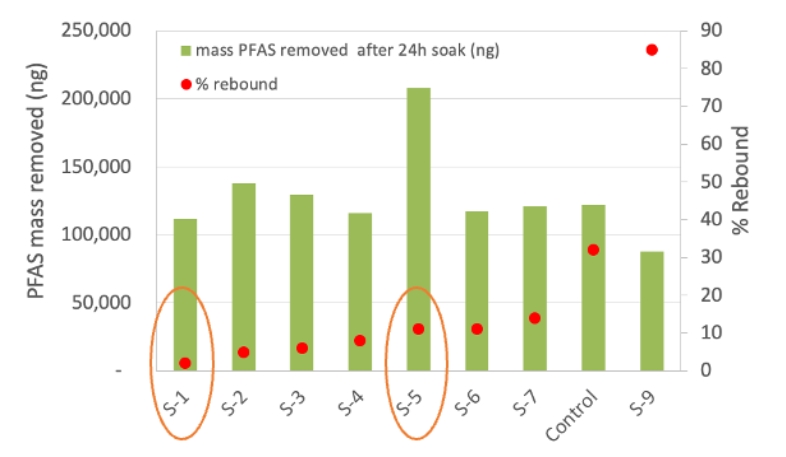

When transitioning from AFFF to SFFF, the asset involved will have to be cleaned to avoid contamination of the fluorine-free foam from residual AFFF that sorbed to the asset over time. This contamination is called ‘rebound’. While rebound is difficult to eliminate, it is important to limit it to the greatest extent practicable. Triple rinsing with water has been used in previous transition projects but a significant rebound has been observed. We have developed a two-part cleaning solution that is differentiated with a) superior PFAS removal results during the cleaning and b) with a reduction in rebound observed after the cleaning. Figure 2 provides data quantifying PFAS mass removed and % rebound.

Figure 2 – In-house experiments demonstrating increased PFAS removal compared to the water (S-5 v. Control) and Lower Rebound compared to the water (S-1 v. Control). Rebound conducted at 24 hours post-treatment.

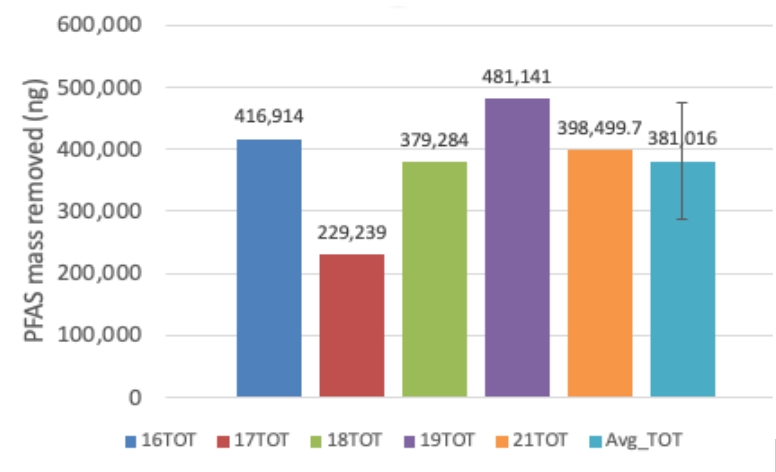

To further improve the effectiveness of the cleaning, our process involves the introduction of both temperature and increased velocity of the cleaning solution. In-house results have demonstrated that these attributes (2-part cleaning solution, temperature, and turbulence) improve the overall cleaning of the asset reducing rebound. Figure 3 provides a subset of our data demonstrating this.

Figure 3 – Increased PFAS mass removed using 2-part cleaning solution and increased temperature and shear velocity. This graph shows the results of sampling conditions #16 – #21. Best-performing solutions and conditions were selected for further optimization and additional rebound evaluations.

Developing cost-effective treatment has been a North Star during our development process and the addition of these steps can be accomplished with minimal cost increases. Minimizing the waste generated can recover some of these costs as discussed in the next section.

Waste Minimization

The shift from Aqueous Film Forming Foam (AFFF) to Synthetic Fluorine-Free Foam (SFFF) necessitates dealing with generated waste, either for further treatment or disposal. Effectively minimizing this waste is critical to keep transition costs in check. A simple triple rinse of assets after removing AFFF and before introducing the new fluorine-free foam results in a significant volume of waste. Moreover, relying solely on water is less effective compared to integrating appropriate cleaning solutions into the process. By including rinsate treatment as part of the procedure, the solution can be reused, enhancing cleaning efficacy and reducing excessive waste generation that would otherwise require additional treatment or disposal.

Conclusion

The transition from PFAS firefighting foams to fluorine-free alternatives is a significant undertaking. Partnering with an experienced team can streamline the approach with demonstrated know-how, differentiated technology, comprehensive service offerings, and an understanding of overall objectives and potential complications to avoid. The journey towards a safer and more sustainable firefighting approach is underway and a collective effort with an established technology- and service- provider in the environmental space will go a long way to ensuring an efficient transition to SFFF.

Montrose Environmental Group, across multiple lines of business, is situated to address your PFAS firefighting foam transition project from start to finish. The subject matter experts at CTEH, ECT2, Enthalpy Labs, Environmental Standards, and MES can provide the experience, technology, and rigor to support you – please reach out to discuss the specific requirements of your transition project.

Dave Kempisty, Ph.D., P.E.

Dave Kempisty, Ph.D., P.E.

Director of Emerging Contaminants

Dave is a licensed engineer with over 20 years of experience in the water treatment and environmental remediation space. His current role at ECT2 focuses on the use of novel technologies for the removal of emerging contaminants such as PFAS, 1,4 dioxane, and carcinogenic volatile organics from the environment. Before this, he spent 22 years in the United States Air Force as an environmental engineer, occupational health consultant, and assistant professor. As editor of two books on per- and polyfluoroalkyl substances and author of over 20 peer-reviewed papers and presentations on a variety of environmental topics, Dave provides a well-balanced perspective on today’s environmental issues.

Nicole Bolea, P.E.

Nicole Bolea, P.E.

Business Development Manager

Nicole Bolea is a professional engineer in Minnesota, she has a degree in chemical engineering and a minor in environmental. She started her career in the water industry designing biological wastewater systems. Now with ECT2, she is excited to help provide solutions related to PFAS, 1,4-Dioxane, and other emerging contaminants. With nearly 10 years in environmental treatment, Nicole now focuses on supporting the energy sector in developing solutions to help solve difficult water treatment problems.