Optical Gas Imaging: Navigating New EPA Methane Rules and Making Detection Quicker, Easier, More Affordable

November 11, 2021

By: Jared Metcalf

The US EPA recently announced a proposed rule* to greatly reduce methane and VOC emissions from the oil & gas industry. One of the important changes to existing rules is the quantification of standards of performance for, and the option to use innovative technologies such as Optical Gas Imaging for fugitive emissions detection. A brief summary of these standards (Appendix K) is outlined below.

Surveys of Process equipment using OGI cameras in oil and gas upstream and downstream sectors.

- OGI Camera Specifications

- Response Factor of 0.25 when compared to the response factor of Propane (type not specified)

- Detect Methane emissions of 17 GPH at 2 meters and a delta T of 5 Celsius with winds of 1mps or less

- Initial Performance Verification and Development of Operating Envelope

- Determine Distance

- Wind Speed

- Ambient Air Temp.

- Background Temp.

- Ensure all Components are Monitored (3 choices)

- Route Map with designated observation locations

- Visual cues such as tags, streamers, or color-coded pipe

- GPS route tracing

- OGI operation

- Each component must be viewed for 5 seconds from two angles (A two component scene would take 20 seconds of dwell time)

- 5-minute break for Technician after every 20 minutes of surveying.

- 10 second video of each leak required

- 5-minute quality assurance video required for each day of surveying

- Operator Training

- Classroom training & Field Test

- 100 site visits required before technician is authorized for independent survey execution

- Quarterly performance audits of 4-hour observations/video

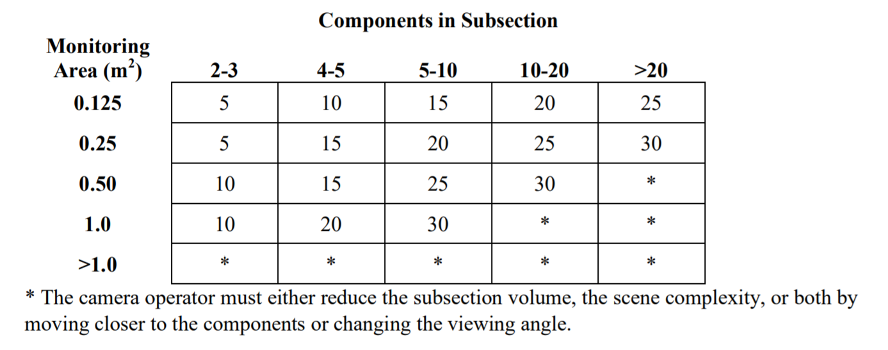

- Maximum monitoring area restricted to 1 meter squared

How is this important to your facility in light of these proposed changes?

Rather than manually monitoring each individual component for leaks, OGI uses infrared cameras to scan facilities up to 20 times faster – including unregulated, unsafe, or inaccessible components that Method 21 can’t always reach. Accuracy increases and mis-identified leaks are eliminated because you’re able to see exactly where a leak is occurring. This efficiency saves time and money and speeds up the LDAR process.

Montrose is the global leader in OGI

We’ve successfully deployed our OGI solution in real-world applications for over a decade – as a compliment and replacement for Method 21. We have experienced teams of OGI, regulatory and subject matter experts at our locations near oil & gas facilities, making our teams intimately familiar with the specifics of your locale. To learn more about how we can assist you with your fugitive emissions management, or help you navigate the proposed EPA rule changes with Optical Gas Imaging, please contact Jared Metcalf.

*For a detailed description of the new EPA rule changes, specifics and impacts, check out Melissa Dakas’ blog here

Jared Metcalf

Jared Metcalf

SVP of Air Emissions Services

Jared Metcalf has over 20 years of Oil & Gas Industry experience. His extensive experience in providing professional fugitive emission monitoring services across North America and internationally has given him the expertise to help our clients meet their compliance/voluntary requirements. Jared specializes in the design, setup, and implementation of LDAR programs using Optical Gas Imaging.