MiQ 101: Understanding this Natural Gas Certification, its Impact, and the Audit Process

March 5, 2025

By: Michael Teeling

Achieving MiQ certification is more than just a badge of compliance—it’s a powerful statement about an operator’s commitment to methane emissions transparency and reduction. As regulatory pressures and market expectations around methane intensify, MiQ offers a structured, independent framework to verify emissions performance and drive meaningful improvements. But what exactly does MiQ certification entail, and how can it benefit operators? This guide unpacks the key elements of MiQ, the certification process, and why third-party verification is crucial for credibility in today’s evolving energy landscape.

What is MiQ?

MiQ is a certification standard which demonstrates an energy sector (typically, oil and gas) operator’s management and handling of natural gas (methane) in a manner focused on the reduction and/or elimination of methane emissions. MiQ stands for “Methane Intelligence” and was developed by the Rocky Mountain Institute (RMI) to create an auditable compliance standard (MiQ’s homepage). More specifically, the certification process mandates independent, third-party verification of emissions, practices, and the tools an operator uses to measure and verify emissions. Following an audit, an operator receives a grade (ranging A through F) for the designated Certification Period. Thereafter, the operator may market certificated gas from the facility (described later).

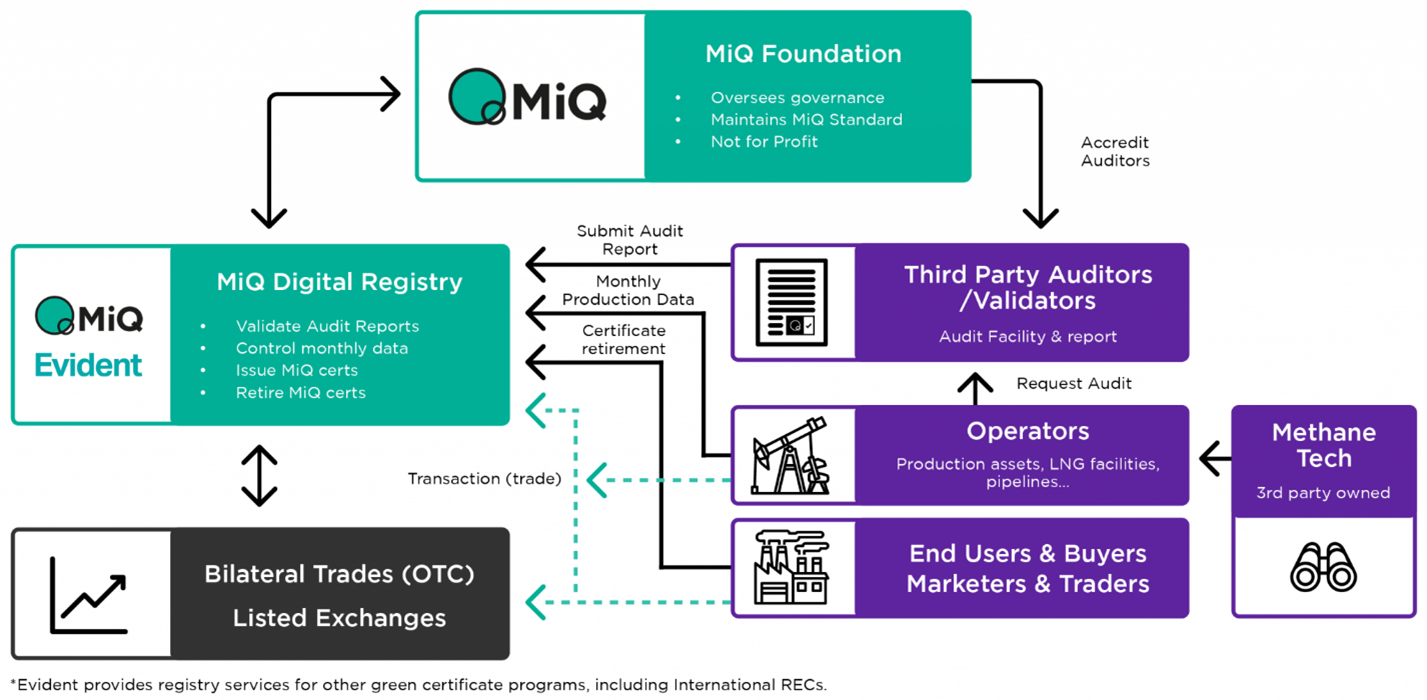

The MiQ Third-Party Independent Governance System

©RMI, 2025 – https://miq.org/technical-information/governance-structure/

The third-party verification component of MiQ certification ensures transparency. Third-party auditors, like Montrose, go through initial screening and annual refresher training by RMI to gain and maintain accreditation. While accreditation is held by the auditing company, specific individuals within the auditing company are certified to perform MiQ audits.

But why go through an audit? Natural gas certification provides a number of unique win-win benefits:

- A transparent objective to reduce emissions and continued improvement

- A marketable product where certificated gas is traded via the digital MiQ Registry (each certificate is equivalent to 1 MMBtu of gas)

- Preferential sale of certificated gas

- Attract buyers of gas seeking to meet their emissions requirements

- Regulatory obligations (e.g., EU Methane Regulation)

Breaking Down MiQ Certification by Operational Segment

Recognizing the distinct assets of the value chain from natural exploration, production, and transport, RMI developed seven individual standards for each segment of operation, primary product, and an eighth for Carbon Intensity, as follows:

- Onshore Oil and Gas Standard for Petroleum Operations

- Onshore Production Standard for Natural Gas Operations

- Offshore Oil and Gas Standard for Petroleum Operations

- Offshore Production Standard for Natural Gas Operations

- Gathering & Boosting and Processing Standard

- Transmission & Storage Standard

- Liquefaction, Shipping and Regasification Standard

- Carbon Intensity Standard

Montrose is certified as an independent auditor by RMI for all the above operational standards.

Before exploring details of MiQ standards, it’s essential to clarify what qualifies an operation to be certified. MiQ defines this as a ‘facility, which can be certified based on either geographic or organizational boundaries.’ This means certification may apply to operations within geologic basin (e.g., Marcellus Shale) or between product transfer points. When preparing for certification, operators must first assess their readiness through a gap analysis and alignment with the three elements of the MiQ audit outlined in the next section. Based on this evaluation, an operator may choose to pursue certification of a single facility or for multiple facilities across different segments of the value chain, as outlined by the standards above.

The Three Elements of an Audit

To ensure consistency across the respective segments, every MiQ Standard employs the same approach under the three elements subject to independent audit of the operations of an auditor’s facility, specifically:

- Methane Intensity (MI)

- Company Practices (CP)

- Monitoring Technology Deployment (MTD)

See below for a brief overview of each element.

Methane Intensity (MI)

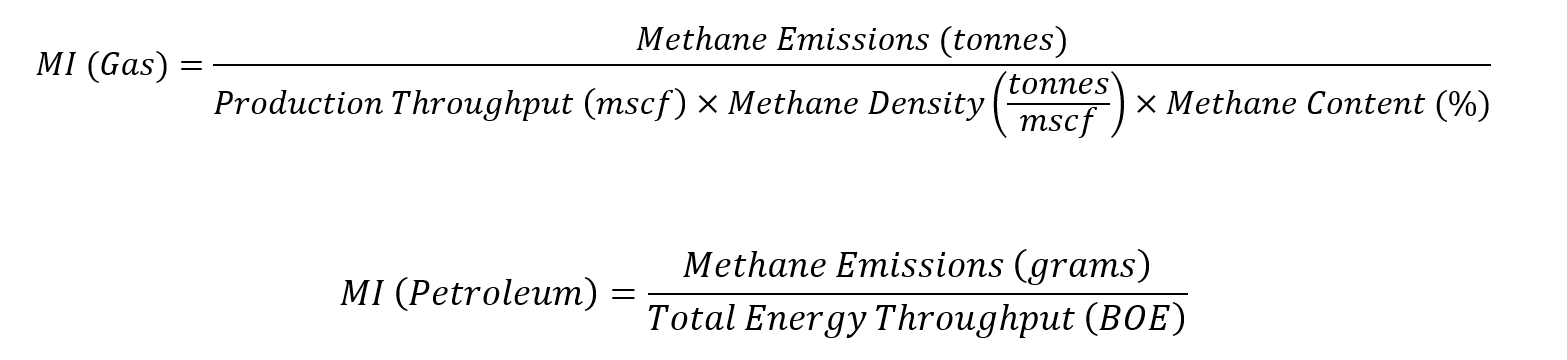

Evaluation of MI comprises the mathematical audit of an operator’s emissions across a year’s timeframe (known as the Certification Period). Furthermore, MI is differentiated for natural gas operations and petroleum (liquids) operations. In practice, it is a unitless number, as a percentage for gas or grams of methane per barrel of oil equivalent, BOE). The following two equations summarize MI by respective operation:

Evaluation of methane emissions includes an audit of the processes an operator uses to estimate and/or specifically measure known intended and/or unintended methane emissions and the assessment of the quantification of the emissions. Furthermore, an operator’s accounting must also include a robust reconciliation or quantitative assessment of material emissions data via the respective technologies deployed to measure and detect emissions. This is an essential step in confirming emissions and assignment of element-specific grading.

Company Practices (CP)

Evaluation of CP involves the detailed review of the protocols an operator has integrated into their processes to specifically address the reduction and/or elimination of methane emissions. CP covers the range of administrative and technological procedures including corporate-level engagement, training, and awareness through the deployment of personnel in the field and the adoption of various equipment (design) to support emissions reductions and the collection, monitoring, and measurement of emissions. Most importantly, the CP audit seeks to confirm the operator’s methods are also described in detail in procedural documentation (e.g., Standard Operating Procedures). While certain practices are a mandatory requirement for grading purposes, improved procedures to further enhance an operator’s management of emissions provide avenues for additional point scoring and grade improvement.

Monitoring Technology Deployment (MTD)

Evaluation of MTD involves the detailed review of the specific technologies deployed by an operator, either self-performed or subcontracted, to measure and quantify emissions at the:

- Source-level – emissions detected from equipment sources on site typically via Leak Detection and Repair (LDAR) protocols

- Facility-level – emissions detected from altitude such as aircraft-borne sensors

Data from both source- and facility-level measurements are reviewed through the MI process (above). Technologies deployed must meet MiQ-specified minimum criteria and be tested by a third-party service to confirm and verify their performance. As part of the evaluation and grading process, the operator must deploy these technologies on a periodic basis to achieve the mandatory minimum requirement. Grade improvement can be attained by more frequent source-level and/or facility monitoring. MiQ also provides supplemental procedural options for “blending” source- and facility-level technologies and emissions thresholds (equivalency) to provide additional avenues where frequency and spatial coverage can be adjusted for operator-specific conditions. Depending on application, grade improvement may be realized using this guidance.

How audits use MiQ Grades and Scoring

Through a series of interviews and on-site audit practices, an operator is evaluated on their adherence to procedures and emissions management leading to respective grading for each element. The following two tables provide the scoring rubric for natural gas and petroleum operations.

MiQ Scoring Rubric (Natural Gas Operations)

| Grade | MI (%) | CP (Improved Practice Points) | MTD (Improved Practice Points) |

|---|---|---|---|

| A | ≤ 0.050% | ≥ 12 | 12 |

| B | ≤ 0.10% | ≥ 8 | 8 |

| C | ≤ 0.20% | ≥ 4 | 4 |

| D | ≤ 0.50% | Mandatory Minimum | Mandatory Minimum |

| E | ≤ 1.0% | Mandatory Minimum | Mandatory Minimum |

| F | ≤ 2.0% | Mandatory Minimum | Mandatory Minimum |

MiQ Scoring Rubric (Petroleum Operations)

| Grade | MI (g CH4/BOE) | CP (Improved Practice Points) | MTD (Improved Practice Points) |

|---|---|---|---|

| A | ≤ 50.0 | ≥ 14 | 12 |

| B | ≤ 100.0 | ≥ 10 | 8 |

| C | ≤ 200.0 | ≥ 5 | 4 |

| D | ≤ 500.0 | Mandatory Minimum | Mandatory Minimum |

| E | ≤ 1000.0 | Mandatory Minimum | Mandatory Minimum |

| F | ≤ 2000.0 | Mandatory Minimum | Mandatory Minimum |

©RMI, 2025

While each element is graded individually, the overall grade for certificated gas is based on the lowest element grade achieved. An operator must meet certain minimum requirements for MI, CP, and MTD in order to achieve a certain grade. Where an operator has made procedural and/or process improvements beyond the MiQ standard for CP and MTD, additional (improvement) points may be acquired, further elevating the grade per element.

Key Takeaways for Getting Started with MiQ Certification

To achieve MiQ certification, operators undergo a third-party verification process, which includes independent audits of emissions practices, measurement tools, and company procedures. The outcome is a grade (A to F) which reflects the operator’s performance over a certification period, with the option to trade certified gas through the MiQ Registry. By earning MiQ certification, operators can enhance credibility, attract buyers interested in sustainable gas, and meet regulatory obligations such as the EU Methane Regulation.

If you are considering MiQ certification, start by familiarizing yourself with the three key elements of the MiQ audit: Methane Intensity (MI), Company Practices (CP), and Monitoring Technology Deployment (MTD). MI evaluates emissions relative to production, CP focuses on emissions reduction protocols, and MTD reviews the deployment of technologies for monitoring emissions. Operators should assess their current operations to understand where they stand in terms of emissions, practices, and technologies.

The next step is to determine which facilities to certify. MiQ allows operators to certify facilities based on geographic or organizational boundaries, which means certification can apply to specific basins or transfer points in the value chain. Operators can choose to certify a single facility or multiple facilities, depending on their operational structure.

Once facilities are selected, operators must work through the audit process, which involves gathering data, implementing necessary improvements, and undergoing third-party evaluations. Each element is graded individually, with the overall grade being determined by the lowest score across MI, CP, and MTD. Achieving a higher grade is possible by improving practices or increasing the frequency of monitoring. Prior to beginning the MiQ audit process, operators may wish to complete a pre-audit gap assessment to identify areas for improvement before engaging an independent auditor.

Ready to be MiQ Certified?

Achieving MiQ certification requires a rigorous, independent audit to verify methane emissions performance, company practices, and monitoring technologies. As an RMI certified independent auditor, Montrose provides access to a team of accredited experts who bring deep industry knowledge, regulatory insight, and hands-on experience in emissions measurement and verification. As an RMI-certified auditor for all MiQ operational standards, Montrose provides an objective, transparent evaluation to ensure your certification process is both credible and efficient. Whether you’re seeking to certify a single facility or multiple operations, Montrose can guide you through gap analysis, audit preparation, and compliance alignment—helping you achieve a strong MiQ rating to enhance your marketability, regulatory standing, and environmental leadership. Get in touch today to take the next step toward MiQ certification with confidence.

Mike Teeling

Mike Teeling

Senior Director

Mr. Teeling has over 38 years of environmental service experience including incident response, field geological oversight, program management, information technology development, and consulting for major energy clients and national and regional law firms and insurance companies. His responsibilities include the performance, management, and supervision of industrial and commercial site assessments and auditing, due diligence, Environmental, Social, and Governance (ESG) auditing (MiQ and EO100), remote sensing and image interpretation, stray gas/mechanical well and (gas) storage field integrity evaluation, litigation support, subject-matter expert, expert testimony and cost allocation, remediation, spill response, regulatory negotiations, and site closure spanning hazardous waste, wet (petroleum hydrocarbons) and dry (shale) gas industries in 45 states (plus the district of Columbia) and three Canadian provinces.

Mr. Teeling is a certified and accredited Lead Auditor for MiQ and Auditor for Equitable Origin EO100. To date, Mr. Teeling has completed more than 150 in-field audits of operator assets to evaluate methane emissions using both hand-held photoionization detector/flame ionization detector (PID/FID) instrumentation and OGI cameras and specifically six (6) MiQ audits and one (1) MiQ gap assessment. Asset segments audited to date include on- and off-shore production, gathering, boosting, transmission, and storage (underground). Mr. Teeling is a subject-matter expert in remote sensing and image interpretation and a FLIR-certified OGI camera operator.