Making the Switch: Bringing OGI-Based LDAR Compliance to Texas Gas Plants

September 9, 2025

By: Michael Kupper, Scott Hyden, and Elizabeth McGurk

A Turning Point for LDAR in Texas

For decades, natural gas processing plants in Texas have followed the same path when it comes to leak detection: Method 21. While effective, it also presents an opportunity to explore more efficient, scalable solutions that better meet the needs of today’s larger and more complex sites.

But that path is changing.

Montrose recently partnered with a major midstream operator to achieve a first-of-its-kind approval from the Texas Commission on Environmental Quality (TCEQ): an Alternate Method of Control (AMOC) that authorizes the use of optical gas imaging (OGI)—without Method 21—as a fully compliant leak detection and repair (LDAR) program. And for the first time, Texas also accepted emission control efficiencies from OGI programs for use in Potential to Emit (PTE) calculations.

As part of this regulatory breakthrough, the operator voluntarily adopted the requirements of the federal New Source Performance Standard (NSPS) Subpart OOOOb and Appendix K, demonstrating a strong commitment to enhanced leak detection standards.

This decision paves the way for a new LDAR compliance standard in Texas—and Montrose is helping lead the way.

Why the Change Was Needed: A History of Permitting Constraints

Most natural gas processing plants in Texas are authorized under one of the following state-level construction permits:

- Standard Permit 30 TAC §116.620 (SP)

- The Non-Rule Standard Permit (NRSP)

- Permit by Rule 30 TAC §106.352 (PBR)

- Case-by-Case New Source Review (NSR)

The Challenge? These permits were written before OGI became mainstream.

Although the EPA officially approved OGI as an alternative to Method 21 back in 2008 for federal programs (Parts 60, 61, and 63), Texas’s SP and NRSP pathways still explicitly required Method 21, with no mechanism to authorize an alternative monitoring method.

Similarly, PBR 106.352 is divided into two categories:

- Subsections (a)–(k), which require Method 21

- Subsection (l), which does not include LDAR conditions

Only PBR 106.352(l) can be paired with an AMOC to authorize OGI as an alternative. For facilities under (a)–(k), transitioning to OGI would require a different permitting strategy.

Under NSR permits, alternative monitoring programs like OGI can be authorized, but only through a permit amendment, which often involves lengthy timelines and regulatory review.

Finally, when it came to emission calculations, Texas only accepted PTE reductions based on M21 LDAR programs, blocking OGI programs from being credited—even if they offered equivalent or better control.

In other words, OGI was federally approved and widely adopted across the industry—but not fully usable under key Texas permits.

The Solution: A First-of-Its-Kind AMOC for OGI-Based LDAR

To address these permitting gaps, Montrose worked closely with a major operator to develop and submit a TCEQ Alternate Method of Control (AMOC) application.

An AMOC allows a company to propose an alternative method of controlling emissions—as long as it achieves equivalent or better environmental outcomes compared to what the regulation requires.

In this case, the operator voluntarily accepted the full requirements of NSPS Subpart OOOOb and Appendix K, including:

- Bi-monthly OGI scans of covered equipment

- OGI monitoring plan and performance validation

- First attempt to repair within 5 days; completed in 15

- Repairs must be verified using OGI or Method 21

- Additional requirements for pressure relief devices and closed vent systems

- Appendix K documentation for calibration, technician certification, and scan record

To streamline compliance, the operator deployed Montrose’s Target Suite—a software solution that automates Appendix K requirements, tracks inspections, stores validation records, and ensures the site remains audit-ready. This significantly reduces administrative burden while maintaining full regulatory compliance.

TCEQ reviewed the proposed approach and agreed:

- The OGI-based program is equivalent to Method 21 for LDAR compliance under SP, NRSP, and PBR 106.352(l)

- The program also qualifies for emission reduction credit in PTE calculations, a first in Texas

This approval created a new, regulatory pathway for gas plant operators in Texas to transition to modern OGI-only LDAR programs—while still meeting all applicable state and federal compliance requirements.

The Benefits for Operators: OGI + Appendix K vs Method 21

OGI-based LDAR programs, especially when aligned with Appendix K, offer clear advantages:

Speed & Coverage

- A plant with 10,000 components might take 20 days to survey using M21, but just 1.5 days with OGI

- OGI scans are faster and less intrusive, reducing downtime

Safety

- Inspections can be done from ground level, minimizing the need for scaffolding, lifts, or confined space entry

Component Flexibility

- OGI can monitor components M21 cannot, such as insulated valves, site glasses, thief hatches, and more

Lower Compliance Risk

- Appendix K requires daily calibration, technician audits, and scan validation

- Montrose’s Target Suite software automates all documentation, making audits painless

Lower Cost

- Operators switching from M21 to OGI may see cost savings up to 30%, due to reduced technician time and streamlined workflows

Better Emissions Control

- When paired with Appendix K protocols, OGI programs offer the same level—or better—of emissions control as traditional M21 programs.

Authorizing an Appendix K OGI Monitoring Program in Texas

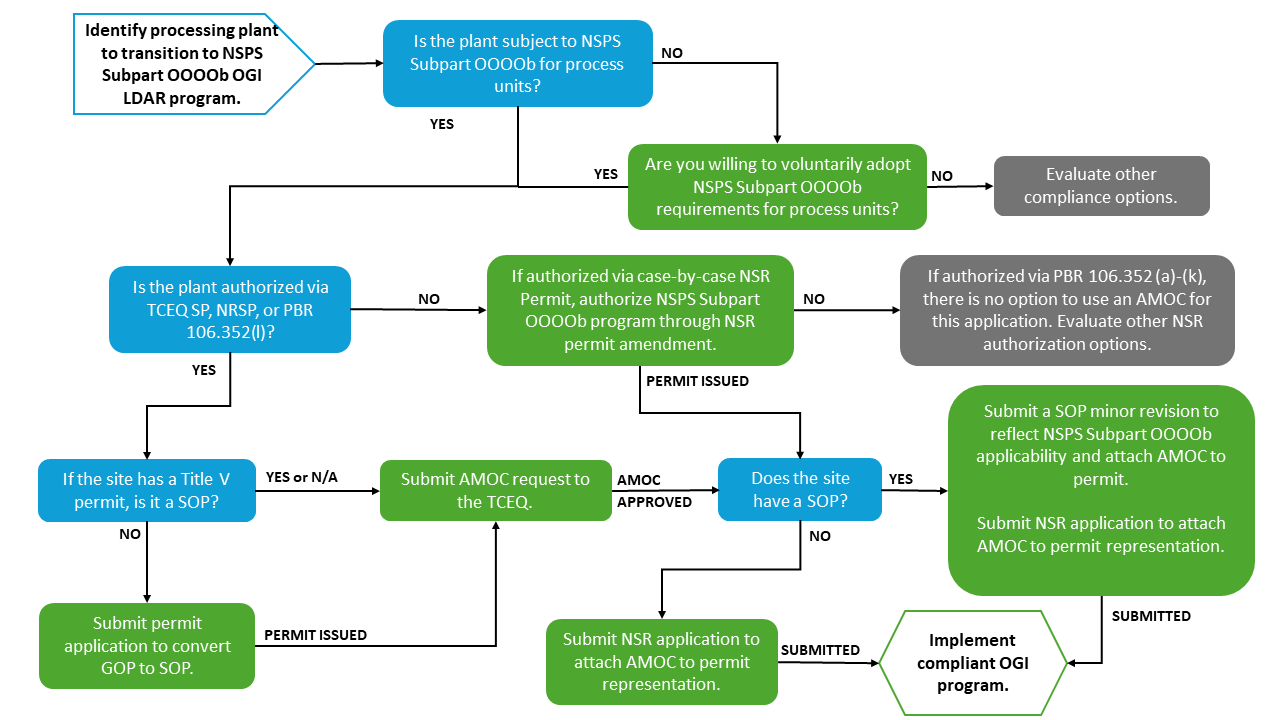

Operators with SPs, NRSPs, or PBR 106.352(l) permits can now follow the same AMOC pathway to adopt OGI-only LDAR programs. However, it’s important to note:

- AMOCs can’t be used for all permits. PBR 106.352(a)-(k) permits still require Method 21.

- General Operating Permits (GOPs) must be converted to Site Operating Permits (SOPs) to use an AMOC.

- After AMOC approval, NSR and SOP updates are required to finalize the change.

For plants authorized under other permitting types, options like NSR amendments may be available to make the transition.

The Future of LDAR is Optical—and it’s Already Here

This AMOC approval isn’t just a Texas milestone—it sets a precedent. As regulators across the U.S. evaluate how to modernize LDAR requirements, OGI-based programs grounded in Appendix K are likely to become the new compliance norm.

Montrose’s experience in securing the first OGI-only approval in Texas puts us in a strong position to help others make the transition—confidently and efficiently.

Want to learn how your site could make the switch to OGI-only LDAR?

Montrose can help navigate the permitting and compliance process. Reach out to begin the conversation.

Michael Kupper

Michael Kupper

Vice President – OGI

Michael is the Vice President of Montrose’s OGI division. Michael has managed and conducted projects for optical gas imaging inspections utilizing a FLIR camera, Tagging and Inventory, Method 21 Inspections, Tank Maintenance, Tank Seal Inspections and Management of Change, as well as Visible Emission Opacity, HRVOC Appendix P inspection, Steam Trap identification and testing, Flare sampling, P&ID walk downs, Highlighting P&ID’s for clients and understanding flow diagrams. He has extensive fugitive emission project management experience including data QA/QC and is an expert in the analysis and interpretation of fugitive emission data.

Scott Hyden

Scott Hyden

Senior Principal, Air Quality – Spirit Environmental

Scott is a Senior Principal in Air Quality at Spirit Environmental, where he has built trusted client relationships for over two decades. Having held multiple roles in client management throughout his tenure, he brings deep technical expertise, long-standing industry insight, and a proven ability to guide clients through complex regulatory challenges.

Elizabeth McGurk

Elizabeth McGurk

Methane Sector Leader

Elizabeth is a highly-experienced air quality program manager with expertise in the fields of greenhouse gas (GHG) quantification and mitigation, oil and gas sustainability framework implementation, regulatory analysis, and auditing. Her passion is in leveraging measurement-informed data to inform effective mitigation efforts, and she is proud to have supported OGMP 2.0 projects worldwide. Elizabeth has a strong background in delivering technical trainings and excels in distilling and presenting complex information, impacts, and solutions to various stakeholders. She leads diverse teams and has conducted complex environmental projects, both regulatorily and voluntarily driven, for clients in carbon-intensive industries. She specializes in assisting clients with Scope 1, Scope 2, and Scope 3 GHG emissions quantification and reporting as well as in developing practical, real-world carbon reduction strategies.