How to use OTM-45 for PFAS Air Testing

June 2, 2023

By: Blake Ericson, Martha Maier, and Bryan Vining

How does OTM-45 work for PFAS testing?

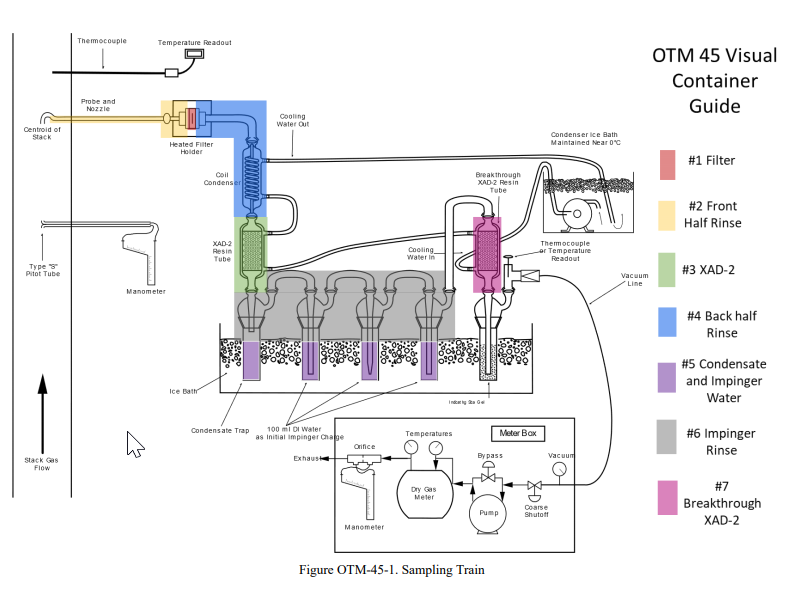

The EPA introduced OTM-45 in 2021 as a benchmark for PFAS stack testing and as a starting point for future PFAS stack testing standards. OTM-45 identifies and determines concentrations in mass per unit gas volume sampled of specific PFAS compounds in source emissions. Gaseous and particulate-bound target pollutants are collected and the target compounds are extracted from individual sample collection media.

An OTM-45 train results in four (4) discreet sample extract fractions for analysis. The extracts are analyzed by LC- MS/MS in the MRM detection mode. The amount of each analyte present is calculated using either the isotope dilution or internal standard techniques.

For quality control purposes, the percent recoveries of the pre-extraction standards are calculated using integrated peak areas of pre-analysis standard(s), which are added to the final extract and function as traditional internal standards, exclusively applied to the pre-extraction standards.

The use of pre-sampling standards added to XAD-2 collection media prior to sampling and analyzed in the same manner as targeted PFAS compounds serve as an indication of the method’s quantitative capture efficiency. This method is not intended to differentiate between target compounds in particle or vapor fractions. The method’s use of isotopically labeled standards dramatically improves method accuracy and precision.

Why OTM-45 & Stack Testing?

As the EPA’s initial approved method for aerial PFAS testing, OTM-45 is the current benchmark for stack testing (we can reasonably expect changes in the near future), but what are the purposes of this testing procedure?

This test serves several purposes, but on a high level, these are the main areas addressed:

- Ensure initial compliance with EPA regulations, plus state & local agency permits

- Conduct test performance guarantee demonstration

- Schedule and conduct periodic monitoring

- Review engineering information including control device optimization and SCR tuning

- Develop and outline emission factors

- Conduct detailed emission Inventories

- Address information Collection Requests (ICR)in a timely manner

OTM-45 Sample Train

Why should your organization care, and remain ahead of the testing and reporting curve?

- The method can support annual Toxic Release Inventory (TRI) reporting.

- Testing can possibly eliminate your facility as a source of PFAS emissions.

- OTM-45 is the current go-to air testing method.

- OTM-45 is performance-based and subject to modification

- OTM-45 has QA/QC at all stages – minimizing chances for inaccurate data and reporting.

- PTFE should not be used.

- Analyses should only be conducted by an experienced laboratory. This part is critical.

What’s Next?

In this blog, we’ve discussed why OTM-45 is a strong starting point for PFAS analysis and measurement of point sources and some of the expectations of using this method. If you want to talk with an expert about this method, please reach out.

Blake Ericson

Blake Ericson

Business Development Manager

Blake’s primary focus is promoting FTIR and FTIR-related technologies in source testing and ambient/fence-line sampling. Mr. Ericson has over a decade of experience in the fields of air quality management, engineering, and regulatory testing; primarily involving FTIR and GC-FTIR technologies. He began as a chemist and analyst for Prism Analytical Technologies in February 2015. Since then he has completed >150 individual projects both solo and with teams throughout the United States and internationally. Mr. Ericson received his MBA and BS in Biochemistry from Central Michigan University.

Martha Maier, PhD

Martha Maier, PhD

PFAS Program Leader

Martha heads the expansive and innovative PFAS Program at Montrose. Formerly the President and Laboratory Director of Vista Analytical Laboratory, located in El Dorado Hills, CA, Martha has been at the forefront of PFAS analysis since Vista developed their in-house analytical method for serum in 2007. She is a member of the ITRC PFAS Committee, as well as the Sampling and Analysis Subcommittee. Before Vista was acquired by Montrose in 2021, she had been the Laboratory Director at Vista since 2002 before becoming the majority owner in 2011. Martha earned her BS in chemistry and philosophy at the University of Wisconsin-Madison. She has over 30 years of experience in environmental chemistry, primarily involving high resolution mass spectrometry for the analysis of chemicals such as dioxins, PCBs and chlorinated pesticides.

Bryan Vining, PhD

Bryan Vining, PhD

Lab Director

Dr. Bryan Vining is the Laboratory Director for Enthalpy Analytical Ultratrace in Wilmington, N.C. where he has led the team for 6+ years. He started his career in the pharmaceutical sector where he developed an expertise in LC/MS/MS and isotope dilution. He then served as the Laboratory Director for a large environmental testing company for 8 years before joining Enthalpy Analytical. Dr. Vining holds a Ph.D. in chemistry from Florida State University and has authored, published, and presented multiple scientific papers on isotope dilution methodology at industry conferences and meetings. Dr. Vining has championed collaborative efforts to develop tools for quantifying and understanding measurement certainty for isotope dilution assays and has considerable expertise in the analysis of environmental contaminants at ultratrace levels in air, soil, and water.