Canada’s New Federal VOC Requirements: What Facility Operators Need to Know

June 6, 2025

By: Marnie Freer, LEL

On March 7, 2025, Environment and Climate Change Canada finalized the Reduction in the Release of Volatile Organic Compounds (Storage and Loading of Volatile Petroleum Liquids) Regulations, commonly referred to as the Federal VOC Regulations Phase 2. The Phase 1 regulations focused on process equipment fugitive VOC leak detection/repair and fenceline monitoring, whereas the Phase 2 regulations are aimed at controlling emissions from petroleum liquid storage tanks and loading racks. Since tanks and loading racks have been identified as significant contributors of VOC emissions, Phase 2 mandates that these sources be equipped with emissions control equipment. The operators of these facilities must install, inspect, maintain, and repair that equipment as well as comply with recordkeeping and reporting requirements.

Who is Regulated?

Facilities subject to the Regulations include most petroleum refineries and upgraders; truck, rail, marine, and pipeline terminals; petrochemical facilities; bulk fuel facilities; and steel mills. Facility exemptions include upstream oil and gas facilities that are already compliant with control provisions under Provincial Methane regulations, gas plants, retail gas stations or cardlocks, offshore platforms, small storage capacity facilities, and remote facilities.

Definitions for Key Regulation Terms

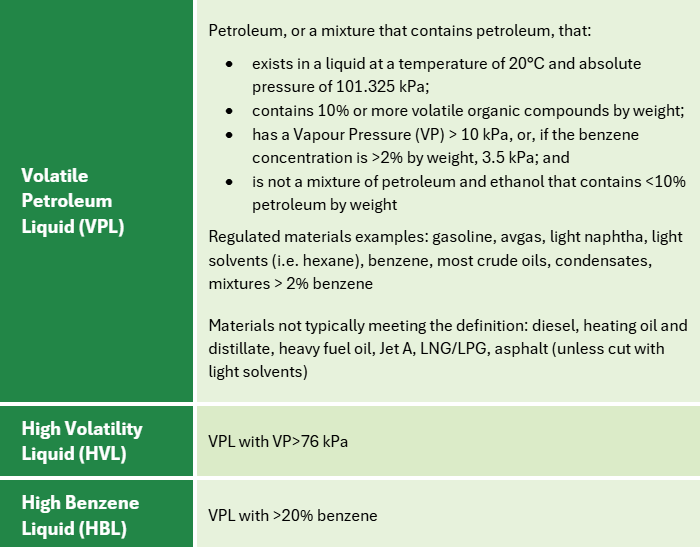

The table below includes key regulation definitions to help determine whether controls are required for your facility.

Required Control Equipment

The required control equipment is determined based on material classification and tank/loading rack properties. A summary table is below:

Timelines for Compliance

In the Regulations, any new tanks, loading racks and control equipment must meet all design and performance criteria immediately. For existing storage tanks and loading racks, a period of 1 to 3 or 4 years is permitted to bring equipment into compliance, depending on its prior condition and emissions risk. There are accelerated timelines for High Benzene Liquid tanks/Loading Racks, but the use of Floating Roof tanks can be extended if a Fenceline Monitoring (FLM) Program demonstrates compliance with specified limits. Then, each year the number of non-compliant tanks must be reduced by a certain percentage. In cases where a large proportion of existing tanks or loading racks require the installation of Emission Control Equipment, up to 7 years may be used to retrofit tanks and up to 5 years for loading racks meeting certain conditions.

What are the Near-Term Deadlines?

- July 5, 2025: Facilities must submit registration documentation, including a detailed inventory of all regulated tanks and loading racks at their facility. This includes information on whether the tank or loading rack is in service, its designation (High Benzene Liquid Tank, Volatile Petroleum Liquid Tank, etc.), and its emissions control equipment.

- July 5, 2025: Requirements to prepare and submit an Action Plan 30 days prior to certain tank maintenance activities.

- September 3, 2025: Facilities with benzene in floating roof tanks wishing to extend the vapour control installation timeline beyond the standard 1-year deadline must submit the FLM Program report.

Your Partner in Meeting Regulation Requirements

Montrose can support your site throughout the implementation of the regulation requirements via:

- Action plan and emissions minimization plan development

- FLM program development/implementation and reporting

- FLM data management and trending to identify limit exceedance risks

- Equipment designation and registration updates

- Tank visual inspections, and support for lower explosive limit (LEL) testing and inspection documentation completion

- Regulatory obligation log preparation with actions and deadlines

Have questions about Canada’s new Federal VOC requirements? Let’s talk. We’re here to support your success every step of the way.

Marnie Freer, LEL

Marnie Freer, LEL

Service Director, Air Permitting & Compliance

Marnie Freer has more than 25 years of environmental consulting and project management experience. Her expertise is focused on regulatory compliance strategy and consultation support, complex emission inventory development, air dispersion modelling and air approvals, and emerging regulation impact. Marnie is a Limited Engineering Licensee with Professional Engineers Ontario, a member of the Air and Waste Management Association, a Past Director of the Sarnia Lambton Industrial Alliance (SLIA), and holds a bachelor’s degree in Environmental Monitoring and Analysis from the University of Guelph.