![Calculating-Methane-Intensity-MiQ[1] Calculating-Methane-Intensity-MiQ[1]](https://montrose-env.com/wp-content/uploads/2025/07/Calculating-Methane-Intensity-MiQ1-scaled-575x300.jpg)

Calculating Methane Intensity for MiQ Certification

July 24, 2025

By: Gary Scoggin

Achieving MiQ certification is a clear demonstration of an operator’s commitment to methane emissions transparency, performance, and accountability. As we explored in our previous article on achieving MiQ Certification, one of the cornerstone metrics of the MiQ framework is Methane Intensity (MI)—a critical indicator of how efficiently an operator manages methane emissions relative to gas and hydrocarbon liquids production.

In this follow-up, we take a closer look at how MI is calculated, providing a practical, step-by-step guide to help operators prepare for certification. This article focuses specifically on gas production and associated liquids, as operations involving combined gas and crude production follow a different MiQ standard.

What is Methane Intensity?

MiQ defines Methane Intensity as:

“The ratio of methane emissions and a selected variable. It accounts for natural gas throughput relative to crude and condensate throughput by allocating emissions that are attributable to the handling of natural gas.”1

Evaluation of MI comprises the mathematical audit of an operator’s emissions across a twelve-month timeframe (known as the Certification Period2). The following two equations summarize MI by respective operation:

The Difference between the Analysis Period and the Certification Period

The MiQ Standard is different from other emissions frameworks in that it is a forward looking standard – emissions are certified for an upcoming twelve-month period. However, to produce this forecast, the prior twelve months of data are used and adjusted to reflect anticipated differences in activities. A similar adjustment should be made for anticipated gas sales volumes so that both numerator and denominator are on the same basis.

The Fundamentals of Calculating Methane Intensity

Calculating MI consists of the following steps:

- Perform a materiality analysis of the different applicable source types.

- For those sources that are deemed material, review the measurement and calculation methodologies used.

- Adjust the inventory to reflect the Certification Period.

- Apply any adjustments for reconciliation.

- Determine the throughput anticipated during the Certification Period, i.e., the denominator of the MI calculation.

- Calculate the Methane Intensity.

We will now explore each of these steps in more detail.

- Perform a materiality analysis of the different applicable source types.

The first step in performing the materiality analysis is reviewing the source types present in the operation. The MiQ standard contains a comprehensive list of source types to be considered.3

Other reporting frameworks such as OGMP 2.0 and Subpart W contain similar, but not identical, lists of sources. (See our discussion “OGMP 2.0: Comparing Direct Measurement Requirements with the Revised EPA Subpart W Rule”.)

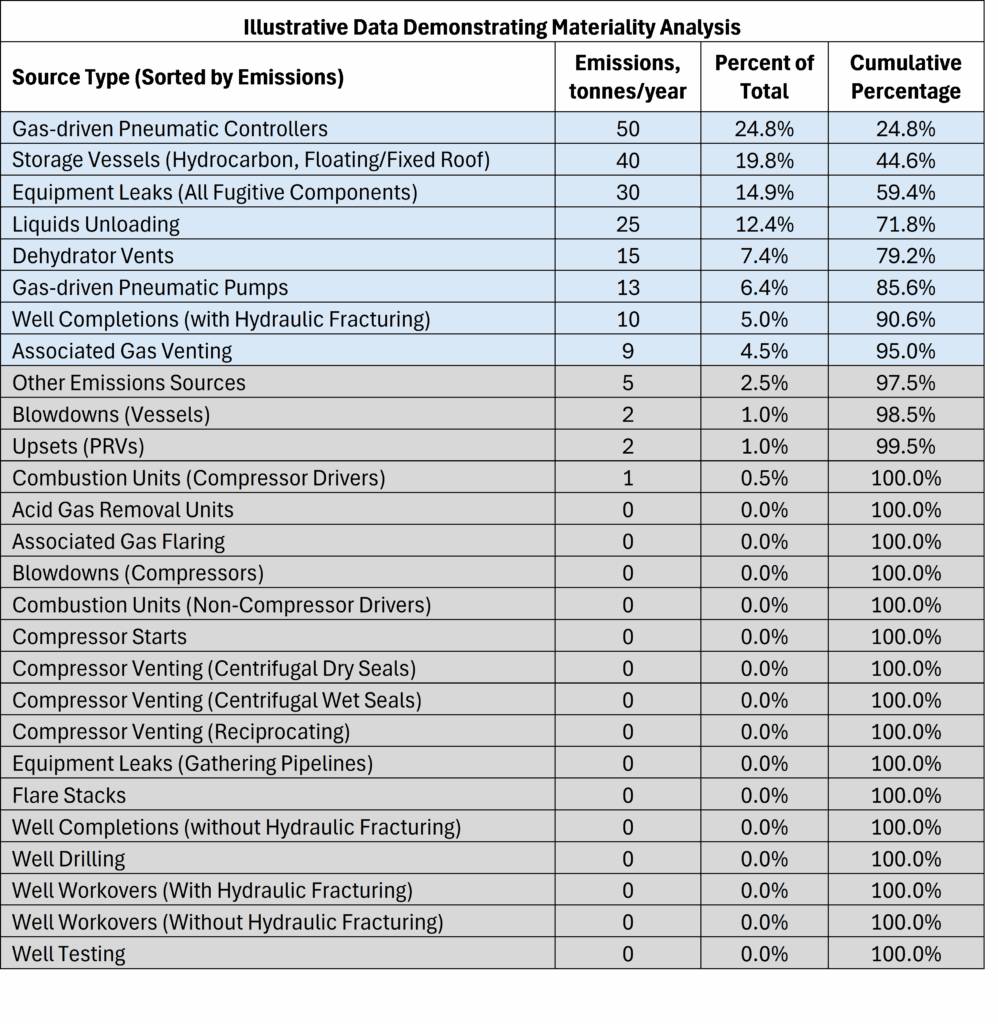

After determining which source types are present at a facility undergoing certification, the next step is to evaluate which of those sources are material to the MI calculation. For this, we look at the percentage each source contributes to the overall menthane inventory. The common approach is to consider those sources that add to 90-95% of the total as shown in the table below.

In the table above, the eight source types shaded blue contribute 95% of the total emissions and are thus deemed material to calculating MI. The remaining source, shaded gray, still contribute to the total emissions to be certified but require a much lower level of further verification.

- For those sources that are deemed material, review the measurement and calculation methodologies used.

Once we have determined which source types are material, the next step is to examine and verify the emissions data presented. While MiQ allows producers great flexibility in determining how emissions are calculated, they do require a minimum level of facility-specific data based on the emission source. The minimum requirements are those listed in EPA Subpart W; however, many operators strive for more rigorous protocols such as those in OGMP 2.0, Level 4.

- Adjust the inventory to reflect the Certification Period.

As noted above, MiQ is a forward-looking standard, whereas the emission inventory to be reviewed is retrospective. Therefore, the inventory needs to be adjusted to reflect the anticipated emissions during the Certification Period. There are several activities which are often considered when making this adjustment:

- Planned emissions reduction projects, such as controls on pneumatic instruments.

- Changes in the number of planned drilling and completions activities.

- Additional facilities coming online or being retired, such as wells, tanks, and separators.

In addition to the changes in emissions inventory, the amount of production planned for the Certification Period needs to be determined. See number 5 below.

- Apply any adjustments for reconciliation.

Reconciliation is the process whereby the bottom-up (or “facility level”) emissions determinations are compared to top-down (or “site level”) measurements of emissions. The facility-level emissions are those described in the points above; the site-level measurements are normally made by aircraft or drone surveys of the facilities. The intent of reconciliation is to identify and explain any significant discrepancies between the two approaches. Often, the facility-level inventory is adjusted – up or down – through the reconciliation process.

Reconciliation can be a complex process at times. There are several different approaches to performing this adjustment. MiQ is generally amenable to a particular approach so long as it is well documented and technically defensible.

We will look deeper into reconciliation in an upcoming blog post.

- Determine the throughput, i.e., the denominator of the MI calculation

As noted earlier, getting the proper denominator in the MI calculation is just as important as getting the correct numerator. MiQ requires the use of the sales volume of gas as the denominator in the calculation.

In cases where natural gas liquids production is material, or in cases of associated gas, the emissions are allocated to the gas and the liquids based upon the relative energy content of each.

- Calculate the Methane Intensity

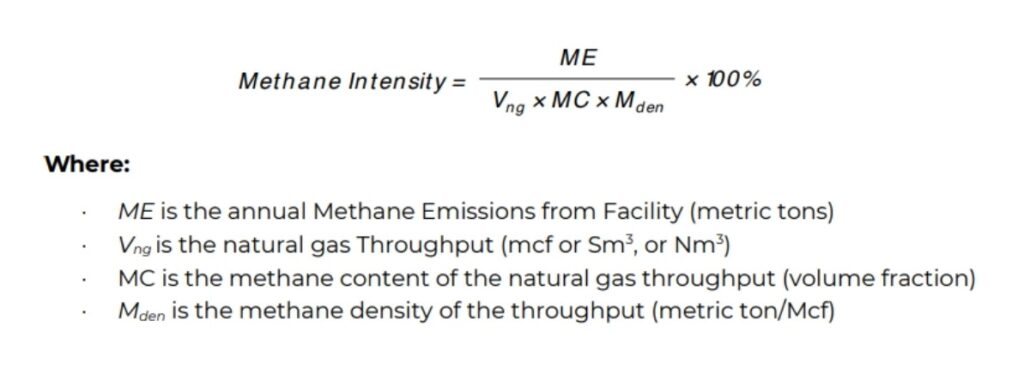

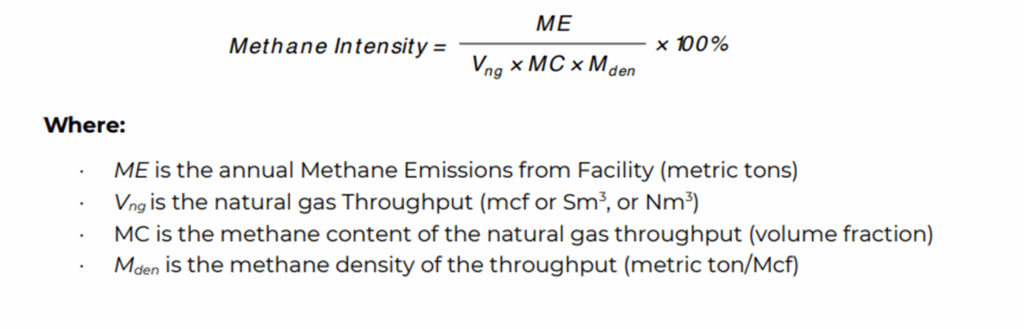

The MiQ equation for calculating MI is

We have already discussed determining ME, the annual methane emissions, and Vng, the volume of natural gas. The methane content of the gas is provided by the producer based on periodic sampling. It is generally consistent across a given field and within an Assessment Period. The natural gas density is normally assumed to be 0.0192 tonnes/mcf.

Ready to Get Started?

MiQ certification requires a rigorous, independent audit to verify methane emissions performance, company practices, and monitoring technologies. With Montrose as your audit partner, you gain access to a team of accredited experts who bring deep industry knowledge, regulatory insight, and hands-on experience in emissions measurement and verification.

As an RMI-certified auditor for all MiQ operational standards, Montrose provides an objective, transparent evaluation that ensures your certification process is both credible and efficient. Whether you’re seeking to certify a single facility or multiple operations, Montrose can guide you through gap analysis, audit preparation, and compliance alignment—helping you achieve a strong MiQ rating that enhances your marketability, regulatory standing, and environmental leadership.

Get in touch today to take the next step toward MiQ certification with confidence.

Footnotes

- MiQ Standard for Methane Emissions Performance for Natural Gas Operations MAIN DOCUMENT – Onshore Production v1.0.0. While MiQ has different standards for different types of operations, this definition of Methane Intensity is consistent throughout.

↩ - The Certification Period can consist of any defined twelve-month period which may or may not correspond to a calendar year.

↩ - MiQ Standard for Methane Emissions Performance, Subsidiary Document 1: Methane Intensity – Onshore Production. Table 3↩

Continue Reading

Gary M. Scoggin, P.E.

Gary M. Scoggin, P.E.

Principal Sustainability Project Consultant

Gary M. Scoggin, P.E. has a long track record of successfully managing environmental programs for industry. He has extensive experience in developing and managing environmental and safety programs for major projects across the US. He has led MiQ certifications in the Marcellus, Utica and Eagle Ford basins as well as in the Gulf of Mexico. As a trained facilitator, he has evaluated environmental and social risk for projects around the world including on the ground experience in the US, Canada, Europe, and Asia.

Gary holds a BS in Civil Engineering from Texas Tech, an MS in Environmental Management from the University of Houston – Clear Lake and has continuing education certificates from Rice University, the London Business School and MIT.