Air Dispersion Models: Meeting Particulate Matter (PM) Regulations

December 17, 2024

By: Roberto Gasparini, PhD, CCM

A recent review of health data by the US EPA suggests that particulate matter (PM) is more hazardous to human health than previously thought. In response, the regulatory landscape continues to evolve with significant reductions to the Federal PM standard to improve public health by reducing pollution-related illnesses. Available headroom under the existing PM standard has been reduced by over 80% in some areas of the country. Unlike unique and specific compounds, PM is a broad category that refers to a mixture of solid particles and liquid droplets in the air. This includes contributions from natural sources such as agriculture, mobile sources such as vehicular traffic, and industrial sources such as manufacturing, construction, transportation, and energy production. Accurate air dispersion modeling is crucial for ensuring compliance and protecting public health.

Given the evolving regulatory landscape, industries must understand what these new requirements mean for their operations and how using the latest air dispersion modeling techniques can ensure compliance.

Federal PM Standards: Implications and Requirements

Regulatory Changes

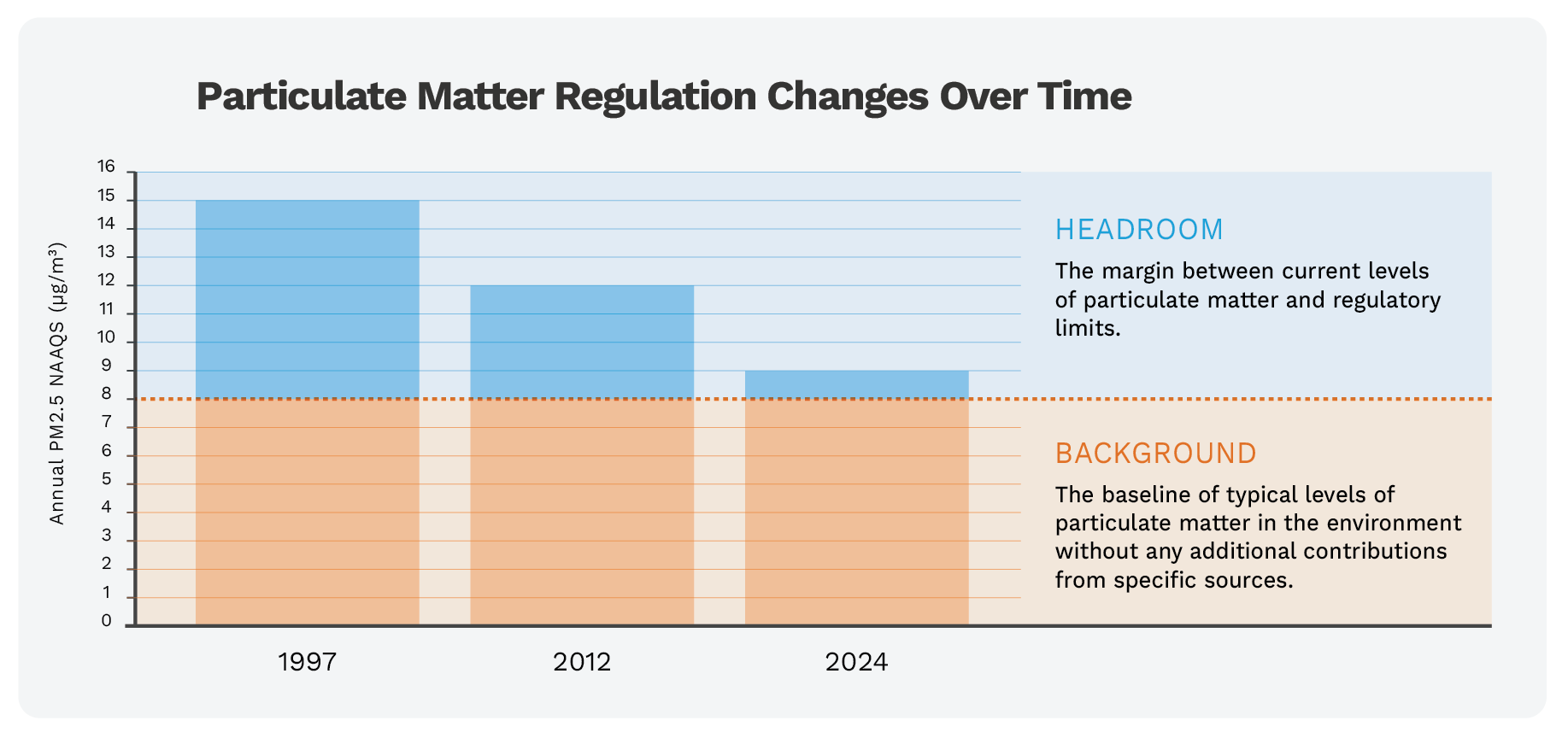

The Federal Particulate Matter Standard is part of the National Ambient Air Quality Standards (NAAQS) set by the U.S. Environmental Protection Agency (EPA). These standards, which are required under the Federal Clean Air Act, regulate PM concentrations to protect public health and the environment. In February 2024, the EPA strengthened the PM standard for the subset of particulates smaller than 2.5 microns in diameter, lowering the primary annual PM2.5 standard to 9.0 micrograms per cubic meter (µg/m3), down from its original value in 1997 of 15 and its revised value in 2012 of 12. This stricter regulation means your facility will likely need air dispersion modeling to ensure compliance with the new standards. With the requirement to consider background, which available monitoring data suggest is typically around 8 µg/m3, that means that available “headroom” dropped from 7 µg/m3 as recently as 2011 all the way down to ~1 µg/m3 today.

Implications for Your Facility

Whether you handle dry materials (e.g., aggregates, food & beverage, solid fuels), spray materials (e.g., coatings, chemicals), or simply burn fuel in support of industrial processes, your facility will face increased regulatory scrutiny. The installation of new equipment or modifications at existing equipment require some sort of air emissions authorization. Air dispersion modeling will be the key element of that demonstration, as the regulator will not approve a project that does not show compliance with the new PM2.5 standard. This evaluation considers the existing background situation and may even include considering emissions from neighboring facilities and integrating them into your modeling process. A comprehensive approach helps create an accurate representation of overall air quality and potential community impacts. To comply with the new standards, we recommend strategically investing in advanced air dispersion modeling techniques, focusing on improving the accuracy of input emission rates and properly characterizing the existing background situation.

How Air Dispersion Models Work

Air dispersion models offer a scientific method to predict pollutant concentrations in the air. These models use inputs such as emission rates, weather conditions, and geographical data to simulate pollutant spread, establishing a high-water mark of potential offsite concentrations to ensure emissions remain within federal air quality limits.

The model, therefore, takes a more easily measurable and known quantity such as emission rates (often in pounds per hour or tons per year) and translates these emissions into predicted ambient air concentration levels. By incorporating meteorological data such as wind patterns and cloud cover, these models predict how emissions will disperse under a variety of atmospheric conditions, ensuring they don’t exceed federal air quality standards. Such a demonstration of protectiveness is necessary for your facility to secure the required approval so that you can proceed with operations.

Any modifications to your facility require a new air dispersion model to reassess compliance. Frequent modeling may be necessary, especially when replacing or implementing new equipment.

The Future of Air Quality Modeling: Trends and Innovations

While improvements to the accuracy and reliability of air quality models moves at a slower pace, advancements in technology continue to enhance the accuracy of key model inputs. For instance, our stack testing group now measures particulate matter with greater precision, quantifying emissions at increasingly lower emission rates and determining the critically important size distribution of those emissions. Better front-end information allows for more accurate modeling and can help your company avoid having to accept operating restrictions in order to secure the requisite permit. Montrose offers integrated services that combine advanced modeling techniques with comprehensive environmental consulting, providing you with robust solutions for air quality management.

Air Dispersion Modeling Win-Win: A Cleaner Future with Permitted Operations

Air dispersion modeling is a cornerstone of environmental management, providing critical insights into pollutant dispersion in the atmosphere. With the ever-evolving landscape of particulate matter regulations and increasingly stringent air quality standards, the importance of accurate and reliable air dispersion models cannot be overstated. Beyond compliance, air dispersion models can serve as a key first step to ensuring the health of surrounding communities, helping to identify areas where direct measurements should be focused. Early and proactive engagement in air dispersion modeling is key to ensuring the permissibility of future projects and safeguarding environmental and public health.

Montrose’s air experts bring decades of experience in a wide variety of industries including chemicals, petrochemicals, refining, oil and gas, power, fertilizer, carbon black, solid waste management, and glass. Contact us today for accurate modeling and expert analysis to stay ahead of the evolving regulatory requirements.

Roberto Gasparini, PhD, CCM

Roberto Gasparini, PhD, CCM

Senior Principal, Spirit Environmental

Roberto has been a dedicated air quality expert since 2000 and an environmental consultant since 2005. As the director of Spirit’s Legal, Audit, & Enforcement Support Program, he specializes in litigation support, due diligence, audits, and regulatory negotiations. Roberto has extensive experience with air quality permitting and is proficient in computerized air dispersion modeling, regulatory applicability assessments, and compliance. He has testified as an expert witness on air quality issues over a dozen times across the US, and he has given presentations at several conferences hosted by trade associations across a number of industries. Roberto has earned distinction by the American Meteorological Society as a Certified Consulting Meteorologist (No. 741). As part of his graduate school research at Texas A&M focusing on particulate matter, which included participating in the Texas Air Quality Study 2000 (TexAQS 2000) and the EPA Supersites Houston project, Roberto authored three papers and co-authored five papers published in peer-reviewed scientific journals.