Achieving OGMP 2.0 Gold Standard: Why Stack Testing is the Missing Link in Methane Measurement

May 22, 2025

By: Elizabeth McGurk & Blake Ericson

In today’s energy landscape, methane emissions reduction has become a defining challenge. Driven by rising expectations from regulators, investors, and global markets, energy operators are under pressure to provide concrete and credible data—not just estimates. According to the International Energy Agency (IEA), methane emissions from fossil fuel operations are around 70% higher than reported figures, underscoring the urgency for more accurate reporting tools.

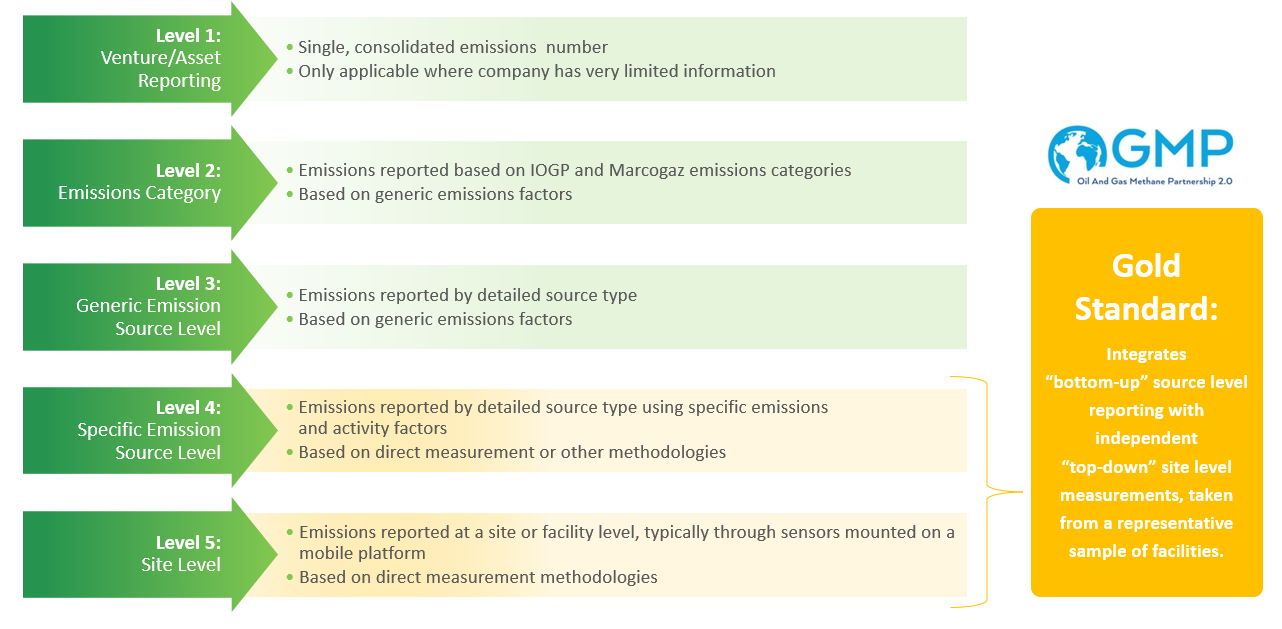

The Oil and Gas Methane Partnership 2.0 (OGMP 2.0), launched by the United Nations Environment Programme (UNEP), is widely regarded as the most rigorous framework for methane disclosure and has been adopted by over 150 oil and gas companies. Its tiered structure prioritizes direct measurement over assumptions to inform emissions reduction strategies—a significant shift from using industry emission factors that’s forcing operators to rethink their monitoring strategies.

We’ve previously explored the fundamentals of OGMP 2.0 and key implementation strategies in our OGMP 2.0 Blog Series—a central resource for operators working to meet these evolving standards.

Many companies have taken early steps by investing in leak detection and venting measurements. However, Fourier transform infrared spectroscopy (FTIR) stack testing, which is highly effective for measuring uncombusted methane emissions (i.e. methane slip), remains underleveraged and misunderstood by many operators. In this piece, we explore how stack testing helps close key reporting gaps, supports OGMP 2.0 Gold Standard achievement, and delivers actionable data in some of the most complex operational environments.

What Stack Testing Really Offers

Getting to the Source

Stack testing involves the direct collection and analysis of emissions from combustion equipment, such as engines, incinerators, and heaters. For sampling via FTIR, the gas is transported through a sample line to a nearby location for continuous, non-destructive, and real-time analysis. By sampling emissions directly from the source, stack testing provides a level of measurement precision and reliability that remote sensing simply cannot match. For OGMP 2.0, achieving Gold Standard status requires reconciling Level 4 (source-level) and Level 5 (site-level) measurements. This makes accurate source-level data and reconciliation not just helpful, but essential.

Surfacing the Unseen

One of the biggest benefits of stack testing is the ability to accurately measure emissions from incomplete combustion, a frequently underestimated source of methane emissions. While these emissions can be detected using aerial technologies, like satellites, drones, and fixed-wing detectors, stack testing remains the most accurate option for measurement as it is performed directly at the source. Several of our clients have found that accurate methane slip quantification helps resolve differences in source-level and site-level measurement reconciliation on their OGMP 2.0 Gold Standard journey.

It’s also worth noting that several other existing methods can overestimate emissions when not validated against direct measurement. Stack testing offers a grounded, verifiable method for anchoring emissions inventories in real-world data.

By bringing combustion-related emissions to light, stack testing strengthens the integrity of reported inventories—ensuring data is not only complete but also defensible.

Lessons From the Field

Requirements for FTIR Stack Testing

Traditionally, stack testing requires significant logistical coordination because it requires many pieces of equipment, several testing methods, and added personnel. FTIR stack testing helps alleviate some of the logistical headaches as less personnel and equipment are required to complete a comprehensive test. The FTIR equipment and peripherals can be packed in a single crate and shipped to site.

To help operators prepare efficiently, we’ve created the below Site Readiness Checklist—a visual reference covering the most important logistical, utility, and operational requirements for FTIR stack testing. Whether you’re planning your first deployment or optimizing your next one, this tool ensures no key details are missed.

Complex Conditions, Consistent Results

Stack testing isn’t new but deploying it in live operations across a global footprint takes experience. Montrose’s stack testing team has extensive experience in executing FTIR measurement campaigns. We have been able to translate our experience to successfully executing FTIR measurements all over the world, often in complex operating conditions, in support of our clients’ OGMP 2.0 goals.

From onshore gas processing plants and offshore rigs to LNG (liquefied natural gas) carriers and remote compressor stations, all OGMP 2.0 projects require a high degree of adaptability.

For example, testing on LNG vessels involves coordinating with multiple international ports, adapting to space constraints, and working under time-sensitive conditions. On remote midstream sites, successful execution hinges on the ability to mobilize quickly and operate in isolation, often in extreme environments. Offshore stack testing requires the ability to support equipment and personnel logistics between land and sea with programs often taking place over several weeks. In these cases, and more, Montrose has supported our clients and accurately measured methane slip emissions from their combustion sources.

Preparation Makes the Difference

One of the most consistent findings across the wide variety of projects summarized above is the value of early planning. Site-specific details—such as equipment manufacturer, make, and rated capacity, historical gas composition, expected flow rates, and prior emissions data—help shape an efficient, targeted testing plan. Understanding and testing under representative operating conditions, a requirement of OGMP 2.0, also requires coordination; note that one site may have several operational conditions that should be tested! Aligning testing with scheduled operational windows avoids repeat visits and reduces costs. To expedite report preparation, site personnel should be prepared to provide data on operational conditions during the testing, including, but not limited to, real-time gas analysis and flow data. A well-prepared single deployment can often capture all required emissions data, minimizing disruption while maximizing measurement value.

Integrating for a Holistic View

Beyond a Standalone Solution

Stack testing is most effective when it contributes to a broader emissions measurement strategy. Combining stack test results with other source- and site-level measurement data improves inventory reconciliation and ensures that no single method becomes a blind spot.

Collaboration Is Key

Achieving OGMP 2.0 Gold Standard often requires input from multiple disciplines—engineers, compliance specialists, data analysts, field technicians, and operations staff. A collaborative approach to methane management enables better decision-making and more accurate reporting. The most successful programs break down silos between field operations and reporting functions to deliver results that hold up to regulatory and stakeholder scrutiny.

Final Thoughts: Stack Testing as a Strategic Tool

Stack testing provides more than emissions data—it provides clarity on an often-misunderstood source of methane emissions. For oil and gas operators navigating OGMP 2.0 requirements, it enables higher-quality inventories, reveals combustion-related emissions that others miss, and helps builds stakeholder trust through data-backed transparency.

As the global standard for methane reporting continues to evolve, stack testing offers a pragmatic way forward: targeted, proven, and increasingly essential.

Where to Learn More

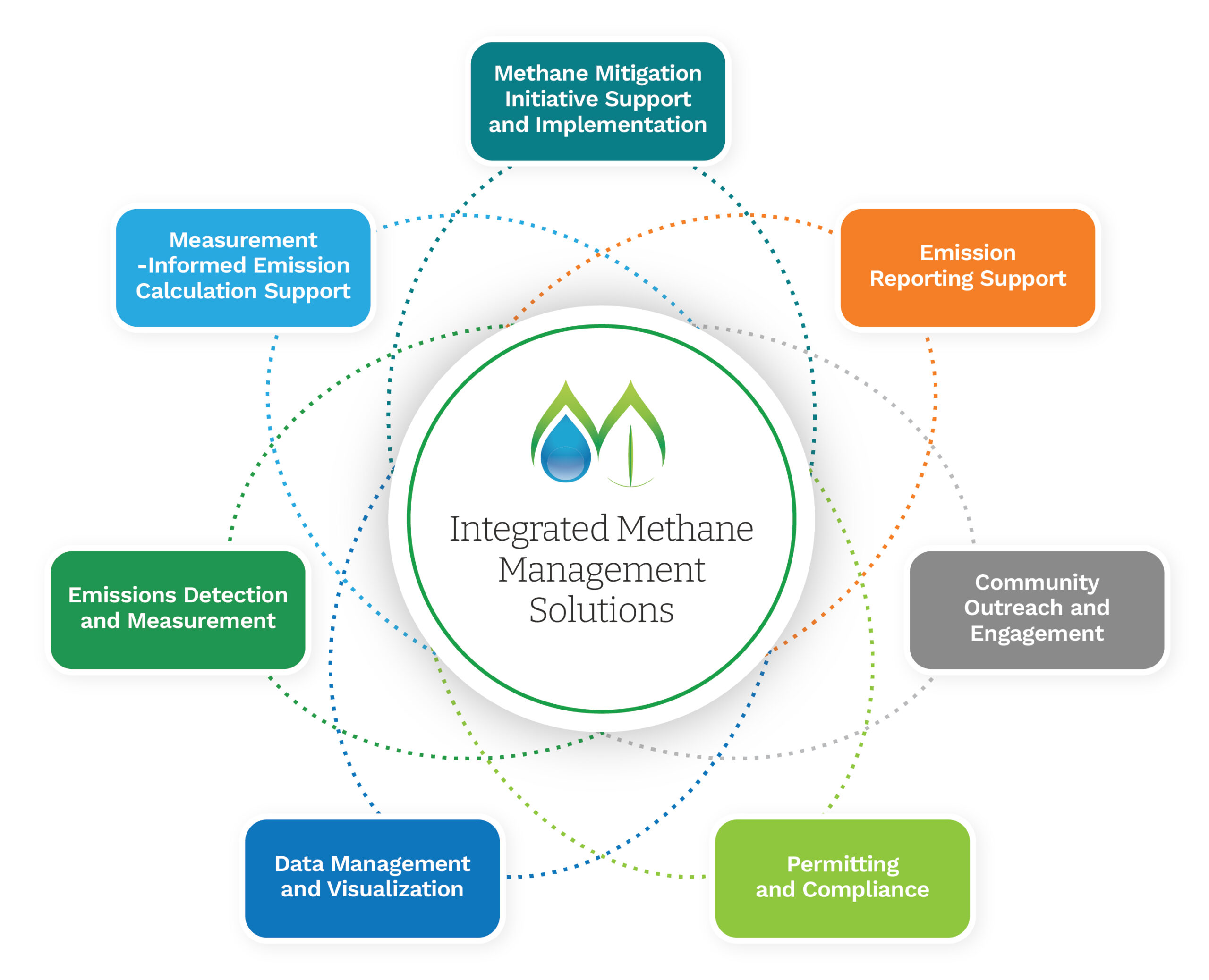

Operators ready to advance their OGMP 2.0 programs should explore how stack testing can integrate with existing monitoring approaches. To find out more about implementing direct measurement strategies or designing a fully integrated methane emissions plan, visit our Integrated Methane Services page or download our Methane Flysheet.

Continue Reading

Elizabeth McGurk

Elizabeth McGurk

Methane Sector Leader

Elizabeth is a highly-experienced air quality program manager with expertise in the fields of greenhouse gas (GHG) quantification and mitigation, oil and gas sustainability framework implementation, regulatory analysis, and auditing. Her passion is in leveraging measurement-informed data to inform effective mitigation efforts, and she is proud to have supported OGMP 2.0 projects worldwide. Elizabeth has a strong background in delivering technical trainings and excels in distilling and presenting complex information, impacts, and solutions to various stakeholders. She leads diverse teams and has conducted complex environmental projects, both regulatorily and voluntarily driven, for clients in carbon-intensive industries. She specializes in assisting clients with Scope 1, Scope 2, and Scope 3 GHG emissions quantification and reporting as well as in developing practical, real-world carbon reduction strategies.

Blake Ericson

Blake Ericson

Business Manager

Blake Ericson is a Business Development Manager for Montrose Environmental Group. Mr. Ericson has almost a decade of experience in the fields of air quality management, engineering, and regulatory testing – primarily involving FTIR technologies. He began as a chemist for Prism Analytical Technologies in February 2015. Since then he has completed hundreds of projects throughout the United States and internationally. Mr. Ericson received his MBA and BS in Biochemistry from Central Michigan University.