Treating Produced Water: Advancing A New Era of Oilfield Sustainability

June 19, 2025

By: Dave Kempisty, Ph.D., P.E.

Water has been called “the new petroleum”—a resource so vital, so finite, and so geopolitically relevant that it could define the course of economies and societies in the 21st century. In water-stressed regions like the Permian Basin of Texas and New Mexico, the intersection of water and energy—known as the water-fuel nexus— represents a key opportunity to advance sustainability and resource efficiency.

Each day, hundreds of millions of gallons of water are produced during hydraulic fracturing operations. Current handling methods are not adequate.

- Saltwater disposal (SWD) wells are under regulatory pressure. Increased seismic activity has triggered volume caps and disposal restrictions in key shale regions.

- Evaporation ponds don’t provide a solution; they only delay the problem. Creating residual waste streams requiring further treatment at a later date, or stated otherwise, legacy contamination.

- Produced water volumes are only increasing. Hydraulic fracturing requires millions of gallons per well—that water and water previously geologically locked in the formation is freed and returns to the surface heavily contaminated.

It’s time to evolve our approach—because better solutions are within reach.

The Case for Reuse: Economics, Environment, and Energy

We believe we can treat produced water at costs comparable to current disposal technologies, all while preserving a critical resource. It’s a bold claim—but one we can back up with experience and know-how.

Our team has treated some of the most chemically challenging waters in the industrial sector. Removing per- and polyfluorinated compounds (PFAS) from complicated water matrices, we’ve pushed the limits of what’s possible. And we’ve done so at scale, treating millions of gallons per day down to non-detect and parts-per-trillion thresholds.

Produced water presents another challenge: the total dissolved solids of these waters are often significantly saltier than the ocean, often exceeding 100,000 ppm. Traditional thermodynamic processes like mechanical vapor recompression are limited by high energy requirements. But by incorporating multi-effect distillation, waste gas recovery, and renewable energy sources, we can meet the energy demands of treatment while maintaining a favorable cost structure.

Once treated, reuse applications are plentiful. Agricultural activities like crop and livestock watering, or process water supplies for a variety industrial activities, or as cooling water for data centers are three examples. Water used for hydrogen production or reintroduced to the environment for aquifer or river replenishment are other examples.

More Than Clean Water: Lithium and Resource Recovery

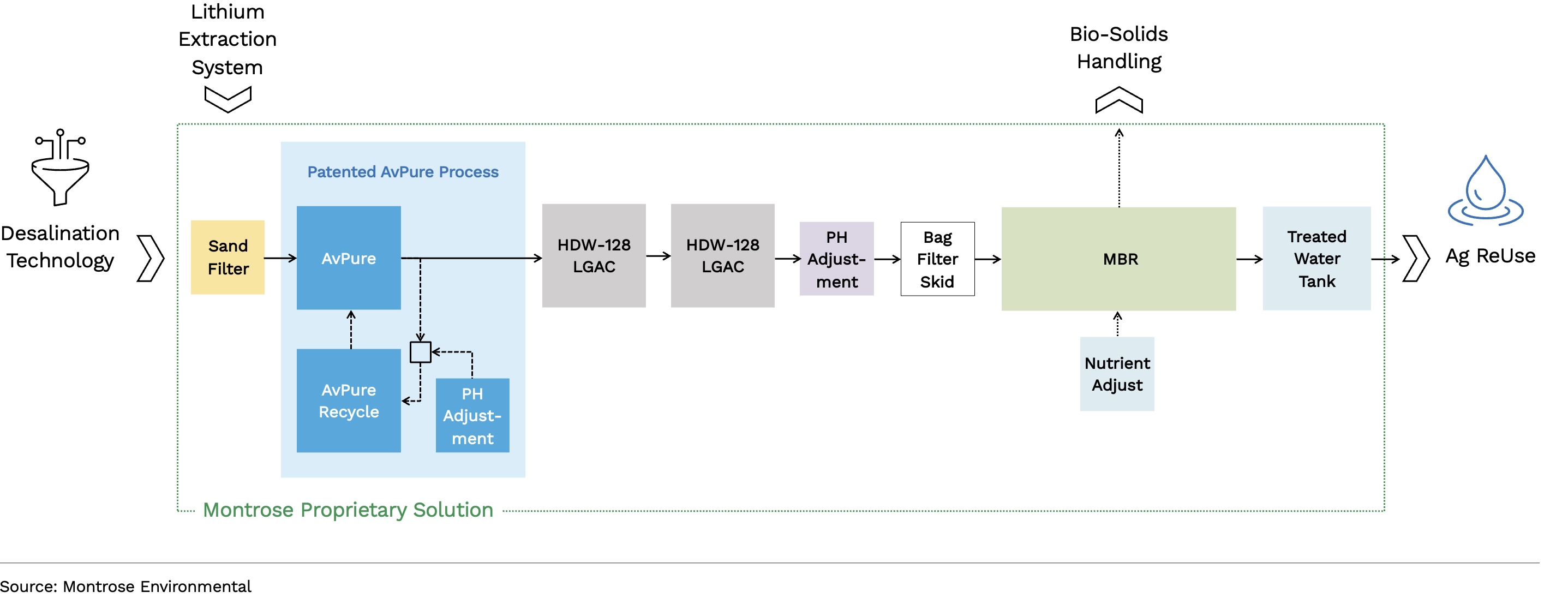

There’s a compelling monetization angle as well. A significant portion of lithium extraction costs stem from drilling continental brine wells and extracting the water. But with produced water, the wells are already drilled, and the water is already at the surface. Using ionic molecular sieves, we can selectively extract lithium from a background abundant in sodium—often 100’s of times more abundant.

The direct lithium extraction technology relies on molecular sieves created with porosity sized to prevent molecules with larger hydraulic radii, like sodium and magnesium, for reaching ion exchange sites. The resins are then regenerated, removing lithium and preparing the resins for subsequent reuse to remove additional lithium.

Optimizing caustic regeneration cycles, managing scaling through antiscalants and pH control, and ensuring proper biofouling mitigation are just a few of the technical challenges we’ve already solved. With routine resin regeneration, built-in process redundancies, and robust system monitoring, we believe we can extract lithium carbonate and/or lithium hydroxide efficiently—and profitably.

Bench- and Pilot-Scale Know-How to Support Full-Scale Operations

Every water source is different. That’s why thorough water characterization and bench-scale testing are essential. Not all elevated TDS and organics present the same issues for treatment. For example, the metal speciation present will affect the scaling potential, while the types of organics (not just concentration) can vary the treatment strategy. Within weeks, we can determine the optimal treatment train, validate the technology, and build trust between vendor and customer. This low-cost, high-impact approach de-risks the investment and accelerates deployment.

Pro-Solution

As a nation, if we are to continue extracting oil and gas from water-stressed regions, we must find better ways to manage the water that comes with it. Pragmatic reuse does that. Produced water can no longer be viewed as a waste product. It is a resource—one that can provide clean water, critical minerals, and environmental resilience.

How we manage produced water will shape not only the future of oilfield operations but also the well-being of the communities and ecosystems that depend on them. With proven technologies, practical solutions, and a shift in mindset, we have the tools to turn this challenge into a defining opportunity for sustainability, innovation, and long-term resource stewardship. We have the chance to do better by choosing a path that supports both energy development and environmental integrity.

Talk to us about produced water solutions.

Dave Kempisty, Ph.D., P.E.

Dave Kempisty, Ph.D., P.E.

Director of Emerging Contaminants

Dave is a licensed engineer with over 20 years of experience in the water treatment and environmental remediation space. His current role at ECT2 focuses on the use of novel technologies for the removal of emerging contaminants such as PFAS, 1,4 dioxane, and carcinogenic volatile organics from the environment. Before this, he spent 22 years in the United States Air Force as an environmental engineer, occupational health consultant, and assistant professor. As editor of two books on per- and polyfluoroalkyl substances and author of over 20 peer-reviewed papers and presentations on a variety of environmental topics, Dave provides a well-balanced perspective on today’s environmental issues.